TM 5-2350-262-20-3

SPOOL AND POPPET VALVE CHECKS

NOTE

The track adjuster cylinders must be retracted to raise or lower

front corner(s). To test spool valve, extend and retract track

adjuster cylinders. To retract track adjuster cylinders, the poppet

valves must be overriden. To override poppet valves (X1 or X2),

depress manual override, rotate 180o counter clockwise and

release (it will be up).

Have assistant start engine.

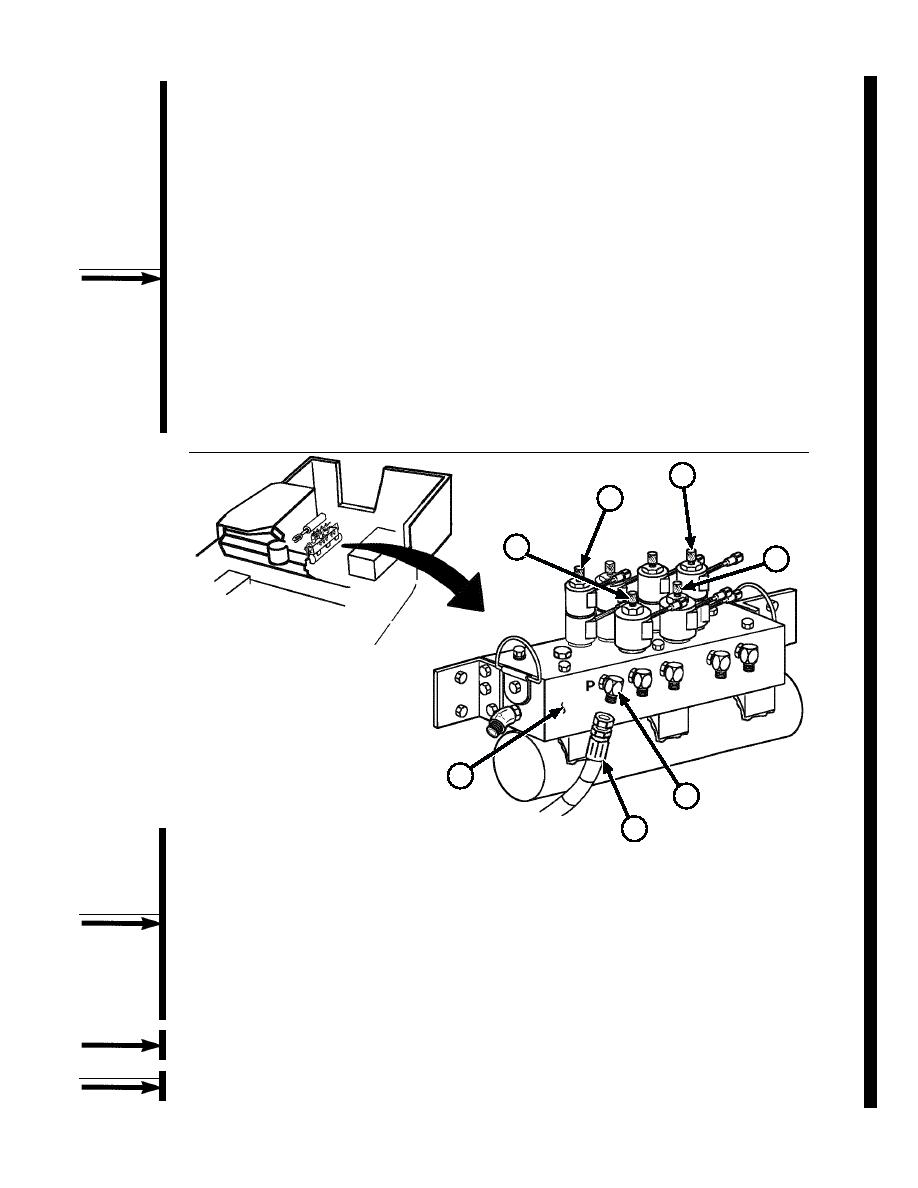

To extend left cylinder, depress manual override spool valve Z4 (1).

To extend right cylinder, depress manual override spool valve Z1 (2).

To retract left cylinder, override poppet valve X2 (3) and lift manual override spool valve

Z4(1).

To retract right cylinder, override popet valve X1 (4) and lift manual override spool valve

Z1 (2).

Stop engine; relieve hydraulic pressure.

1

2

4

3

7

6

5

OIL FLOW TEST

NOTE

Have suitable container ready to catch oil.

Disconnect HYDR-MAN-IN-9 hose (5) from elbow (6) at port P on track adjuster manifold

(7). Cap elbow (6).

While holding open end of hose (5) in container, have assistant start engine. Check for

free flow of hydraulic oil from hose (5).

Stop engine; relieve hydraulic pressure. Connect hose (5) to elbow (6).

Refer to TM 5-2350-262-20-2.

Perform Semi-automatic track adjuster electrical troubleshooting, refer to TM 5-2350-262-20-1.

Change 1

3-241