TM 5-3800-205-23-1

TESTS, INSPECTIONS, AND ADJUSTMENTS - CONTINUED

0005 00

EMS AIR SYSTEM CHECK - CONTINUED

m.

Action alarm and light must operate at 60 psi (415 kPa).

n.

Stop engine (TM 5-3800-205-10-1 or TM 5-3800-205-10-2).

o.

If action alarm and/or light do not operate at correct pressure, check electrical connections for the following com-

ponents: action alarm, light, and pressure switches. Check bulb for light switch.

p.

If connections are good, replace pressure switch or switches (WP 0047 00).

AIR SYSTEM PRESSURE TEST

Tools and Special Tools.

1.

a.

Tool kit, general mechanic's (Item 33, WP 0172 00).

b.

Tool outfit, hydraulic systems (HSTRU) (Item 35, WP 0172 00).

Equipment Condition.

2.

a.

Engine OFF (TM 5-3800-205-10-1 or TM 5-3800-205-10-2).

b.

Battery disconnect switch in OFF position (TM 5-3800-205-10-1 or TM 5-3800-205-10-2).

Air System Pressure Test.

3.

WARNING

Always wear eye protection when draining air tanks. Failure to do so could result in injury.

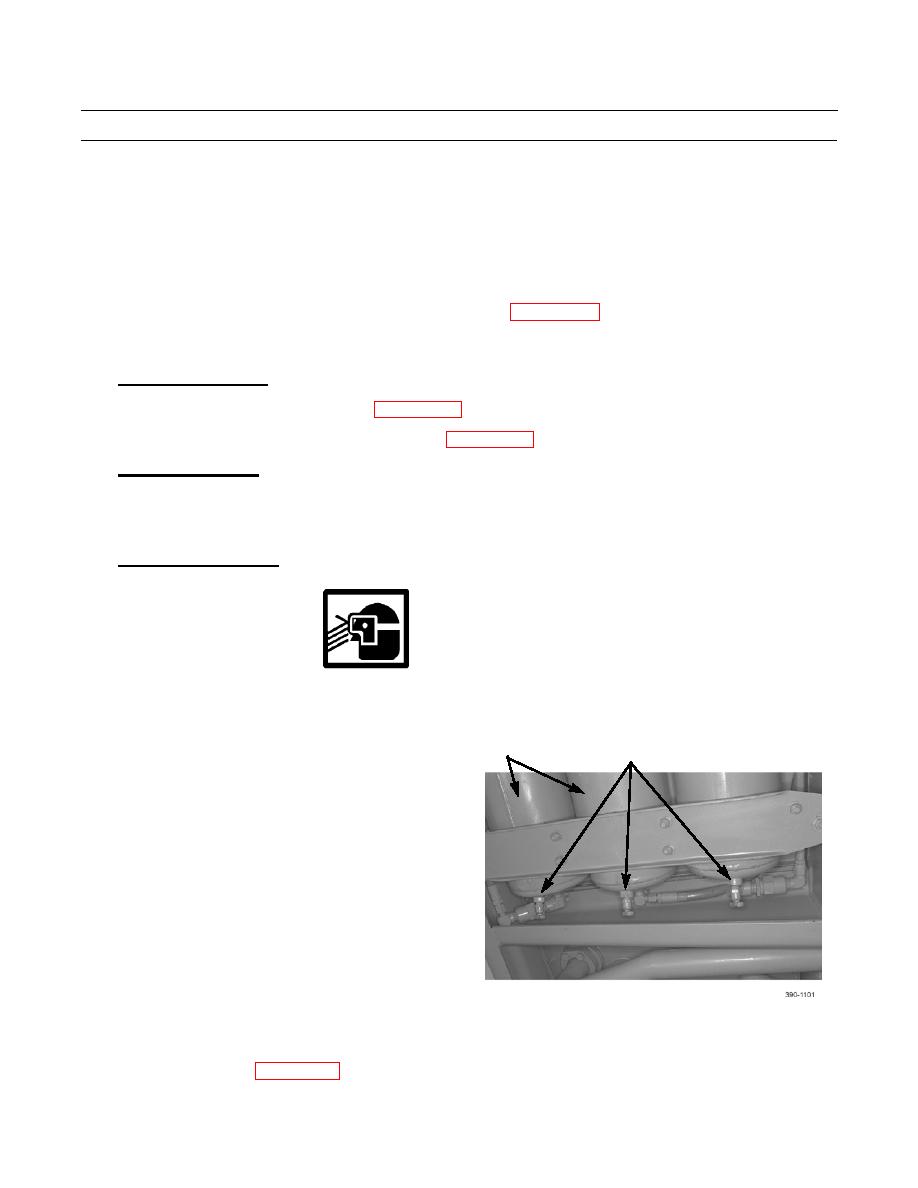

a.

Open three drain valves on air tanks to release air

AIR

DRAIN

pressure from air tanks.

TANKS

VALVES

b.

Remove drain valve from one air tank.

c.

Install bushing and hose assembly to air tank

where drain valve was removed.

d.

Connect other end of hose to needle valve.

e.

Connect 290 psi (2000 kPa) gage to valve.

f.

Start engine (TM 5-3800-205-10-1 or TM 5-

3800-205-2) and allow air pressure to reach cut-

out pressure of 125 psi (860 kPa).

g.

Compare indications of air pressure gage on

machine and test gage. The difference between

two gages should not be more than 15 psi (105

kPa). If this condition exists, replace air pressure

gage on machine (WP 0042 00).

0005 00-12