TM 5-3805-248-23-2

MAINTENANCE ALLOCATION CHART (MAC) - CONTINUED

0338 00

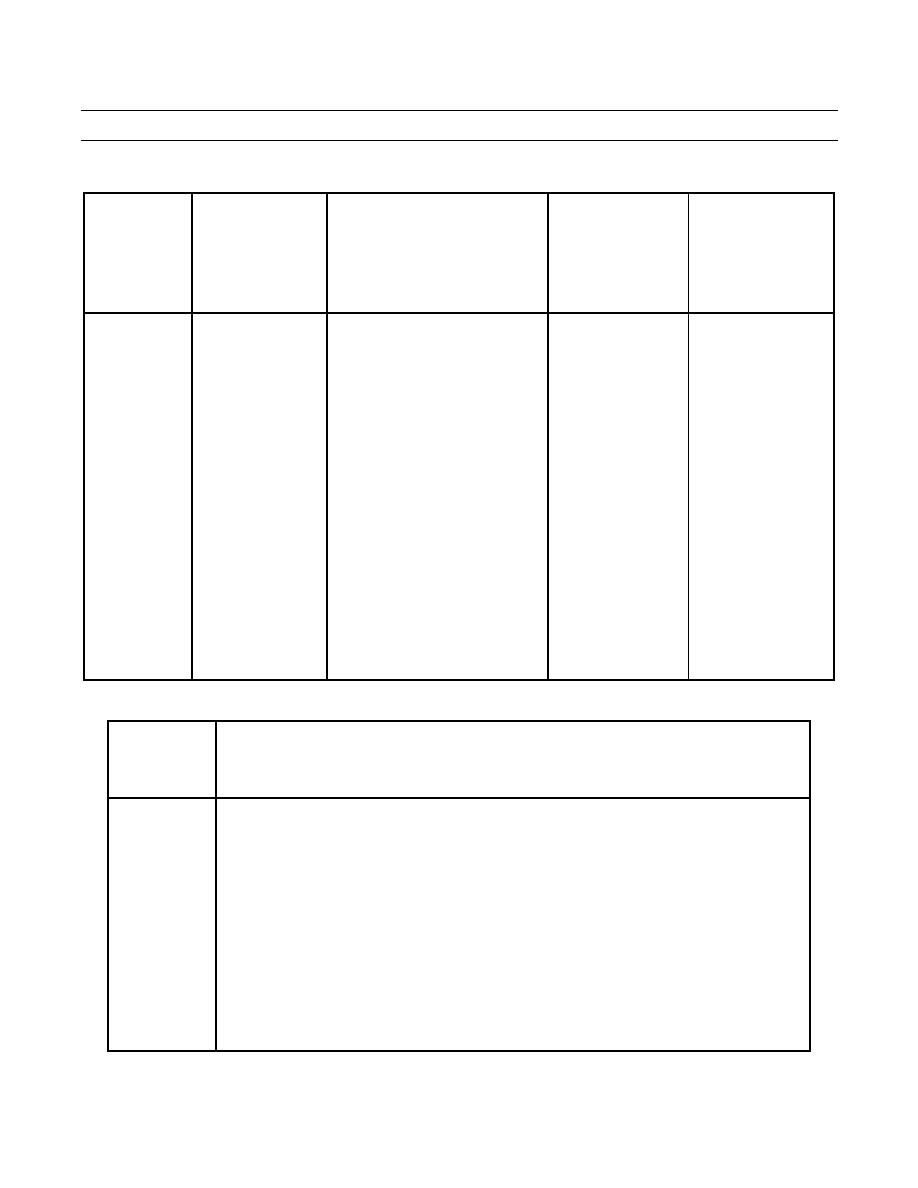

Table 2. Tools and Test Equipment Requirements for 621B Scraper - Continued.

(2)

(3)

(4)

(5)

(1)

TOOLS OR

TEST

EQUIPMENT

NATIONAL

REFERENCE

MAINTENANCE

STOCK NUMBER

CODE

LEVEL

NOMENCLATURE

(NSN)

TOOL NUMBER

112

H

Tool Kit, Fuel Injection

6V6070

113

O

Tool Kit, General Mechanic's:

SC5180-90-CL-N05

Automotive, SC5180-90-CL-N05

114

F

Tool Outfit, Hydraulic System Test

SC3470-95-CL-B07

and Repair (HSTRU)

13221E6850 (97403)

115

F

Tool, Alignment

6V3069

116

F

Tool, Drive

6V0188

117

F

Tool, Pump

Assembly,

Fuel

5P2391

Transfer

118

F

Tool, Pump

Assembly,

Fuel

5P2392

Transfer

119

O

Tool, Special (Fd & Track)

8S7611

120

F

Tool, Valve Lifter

5120-01-276-0528

5P7433

121

F

Tube Assembly, Metal

7N8371

122

H

Turbine Holder

4910-01-181-5660

8S9944

123

H

Wrench, Bonnet

5120-01-266-7433

8T5287

124

O

Wrench, Ratchet

5120-01-123-5881

8H0684

Table 3. Remarks for 621B Scraper.

(1)

(2)

REFERENCE

CODE

REMARKS

A

Inspect by checking lubricating oil level and checking for leaks.

B

Service by changing oil.

C

Valve mechanism adjustment consists of measuring clearance between rocker arm and valve turning

adjustment screw. Procedure also indicates how to locate Top Dead Center (TDC) compression

stroke for no. 1 piston.

D

Includes removal of suction bell.

E

Fuel injection pump timing checks can be performed with engine installed or removed.

F

Inspect by checking coolant level and by checking for leaks.

G

Battery maintenance instructions are provided in TM 9-6140-200-14.

H

Inspect by checking transmission oil level and checking for leaks.

I

Service by lubrication.

J

Check for damage and missing or loose bolts.

K

Service by changing hydraulic system oil.

END OF WORK PACKAGE

0338 00-22