TM 5-3805-248-23-2

CONTROL GROUP PRESSURE TEST - CONTINUED

0284 00

TESTING

1.

Connect battery negative ground (WP 0104 00).

HAND LEVER

2.

Operate engine (TM 5-3805-248-10).

3.

Allow engine to reach operating temperature.

4.

Turn hand lever until tachometer on transmission

hydraulic test set reads 750 RPM.

394-825

NOTE

All pressures recorded will be used in later steps. Engine RPM, transmission speed and tap designation (A,

B, C, D, E and F) should also be recorded for later reference purposes.

5.

Record pressure gage readings for taps A, B and C, engine RPM and transmission speed.

6.

Position transmission speed select lever in NEUTRAL.

7.

Record pressure gage readings for taps A, B and C, engine RPM and transmission speed.

8.

Turn hand lever until tachometer on transmission hydraulic test set reads 900 RPM.

9.

Shut down engine (TM 5-3805-248-10).

10.

Vent air tank (TM 5-3805-248-10).

11.

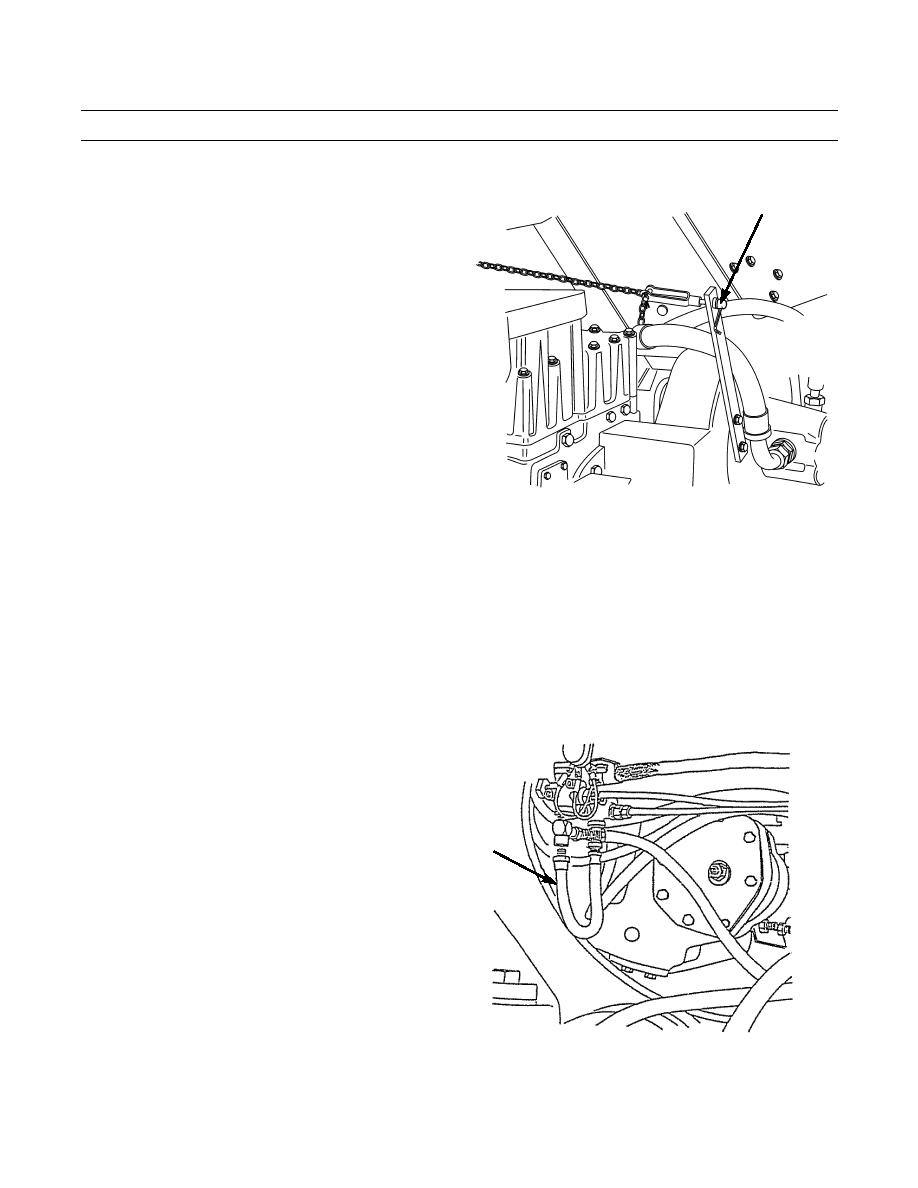

Disconnect air line (7) from transmission hold valve

under operator compartment floor.

12.

Install 0-100 psi air pressure gage in transmission con-

7

trol valve.

13.

Connect air line (7).

14.

Operate engine (TM 5-3805-248-10).

15.

Observe 0-100 psi air pressure gage reading. If read-

ing is less than 65 psi, transmission control valve may

need replacement or repair (WP 0174 00).

16.

Shut down engine (TM 5-3805-248-10).

17.

Disconnect air line (7).

18.

Remove 0-100 psi air pressure gage.

394-826

19.

Connect air line (7).

0284 00-5