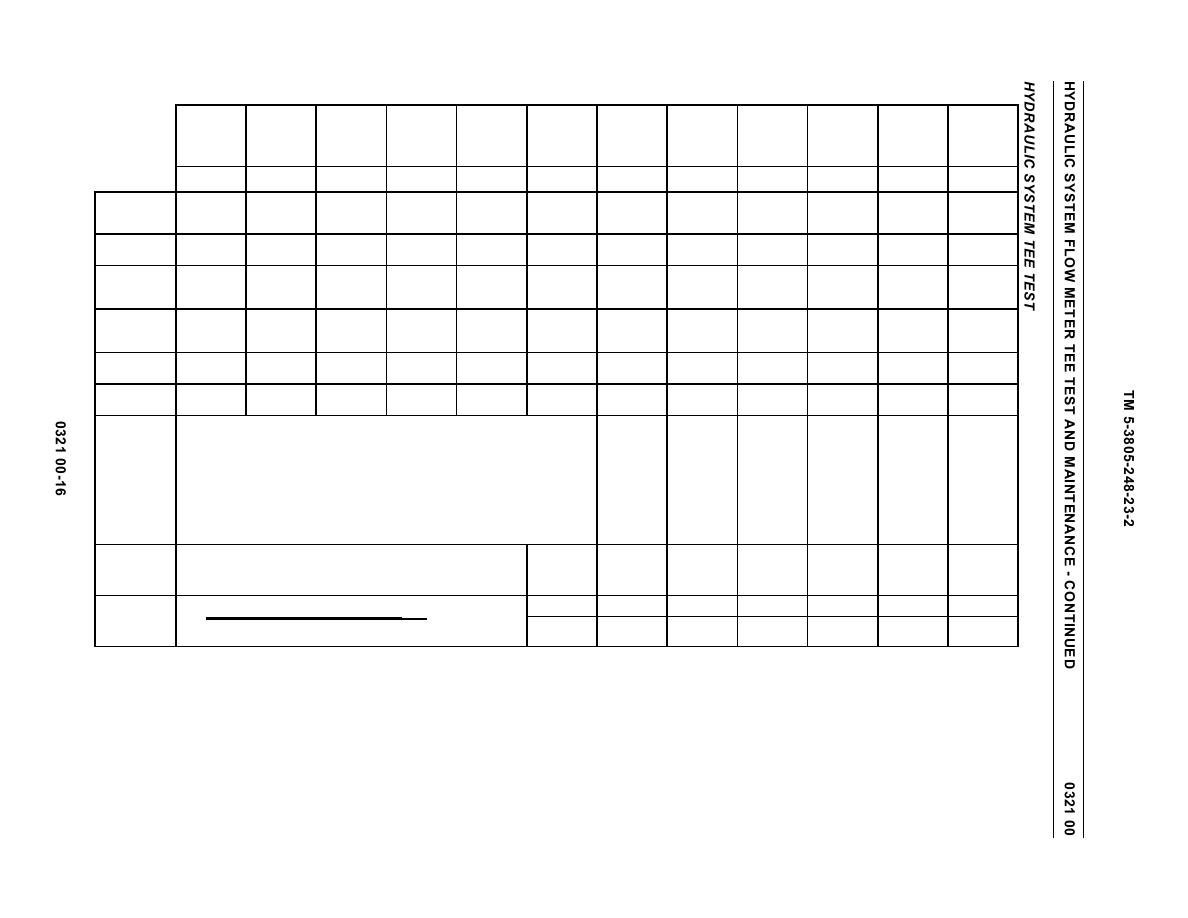

Table 1. Hydraulic System Tee Test.

Maximum

System Oil

Pressure

Temp-

Ejector

System Oil

Bowl Circuit

Apron

Relief Valve

erature

System Base

Forward

Bowl Raise

Bowl Raise

Bowl Lower

Apron Up

Apron Down

Temperature

Drift

Circuit Drift

Setting

(Start)

Flow Rate

Flow rate

Flow Rate

Flow Rate

Flow Rate

Flow Rate

Flow Rate

(End)

Compare

Compare

1

2

3

4

5

6

7

8

9

10

11

12

Apron

Ejector

Bowl Hold

Apron Hold

Control Lever

Ejector

Ejector

Ejector

Ejector

Apron Up

Bowl Raise

Bowl Raise

Bowl Lower

Raise

Position

Forward

Forward

Forward

Return

Down

Forward

Raise

Engine Speed in

1,900

Any Speed

1,900

1,900

1,900

1,900

1,900

1,900

1,900

Any Speed

Low Idle

Low Idle

RPM

System Test

Maximum

0-100

100 (689)

1,000 (6,895)

1,000 (6,895)

1,000 (6,895)

1,000 (6,895)

1,000 (6,895)

1,000 (6,895)

0-100 (0-689)

0

0

Pressure - psi

(0-689)

(kPa)

Test Data

2,100-2,200

145-155F

79 gpm

67 gpm

67 gpm

67 gpm

63 gpm (239 l/

67 gpm

67 gpm

145-155F

Hold M S

Hold M S

psi (14,479-

(63-68C)

(300 l/min)

(254 l/min)

(254 l/min)

(254 l/min)

min)

(254 l/min)

(254 l/min)

(63-68C)

15,168 kPa)

Flow

12 gpm

12 gpm

12 gpm

16 gpm

12 gpm

12 gpm

Raise M S

Raise M S

Differential

(45 l/min)

(45 l/min)

(45 l/min)

(61 l/min)

(45 l/min)

(45 l/min)

Percent Flow

15%

15%

15%

20%

15%

15%

Loss

Finish oil temperature, Test 10 must be within ten percent 15F (-9C) of start oil

System Oil

Temperature:

temperature, Test 2.

For each 15 degrees that the finish is higher than the start, Test 10 greater than Test 2,

subtract 0.5 gal. from the leakage rate.

For each 15 degrees that the finish is lower than the start, Test 2 greater than Test 10,

add 0.5 gal. to the leakage rate.

Flow Differen-

tial Calcula-

tion

System Base Flow Rate - Test Flow Rate

(System Base Flow Rate - Test Flow Rate)

X 100

Percent Flow

System Base Flow Rate

Loss