TM 5-3805-260-24

CRANKSHAFT AND GEAR

INSTALL CRANKSHAFT AND

GEAR

Tools Needed

A

B

8S2328

Dial Test Indicator

Group

1

5B1161 Wire

*

I.

Install the key for the crankshaft gear so it is

even with the end of the crankshaft.

2.

Heat the crankshaft gear to a maximum

temperature of 500°F (2600C).Install the gear

on the crankshaft with the '"V'' mark on the

gear toward the pulley end of the crankshaft.

3.

Install the thrust bearing for the No.4 main.

4.

Make sure the upper main bearings are clean.

Put clean oil on the upper main bearings and

journals of the crankshaft. Install the upper

main bearings (the bearings with oil hole) into

the engine block.

5.

Install two of the bolts that hold the flywheel in

place in the end of the crankshaft. Fasten a

hoist and put the crankshaft in position in the

block. Make sure the timing mark on the

crankshaft gear is in alignment with the timing

mark on the cam-haft gear.

For more detail about installation of main bearings see REMOVE

AND INSTALL CRANKSHAFTMAIN BEARINGS.CAUTION:

When the bearing caps are installed{3.100} make sure the

number on the side of the cap is next to and respective with

the number on the engine block.

6.

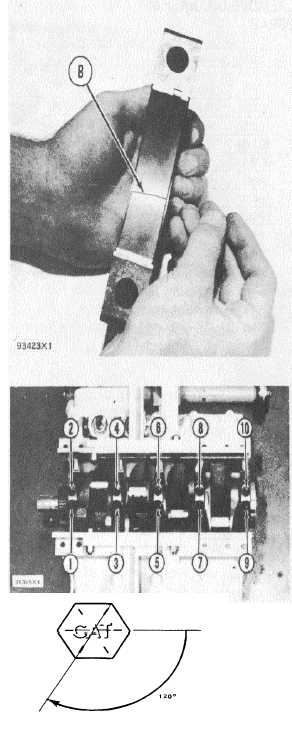

Check the bearing clearance with wire (B).Put

the lower main bearings into the caps. Put the

caps in position and install the bolts. Tighten

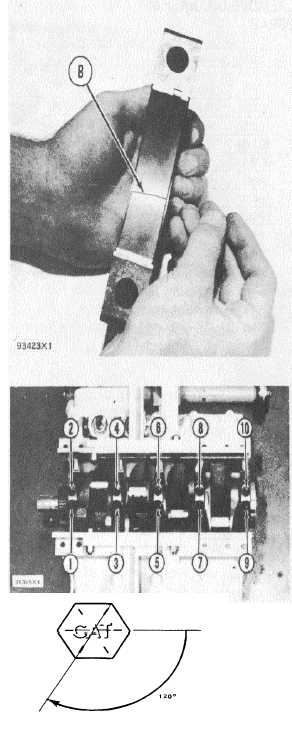

the bolts in number sequence as follows:

a)

Tighten bolts I through I 0 to a torque of 30

+3 lb. ft.(4 4 N m).

b)

Put a mark on each bolt head and bearing

cap. Tighten bolts 1 through 10 120° _

5° more.

3-142