MWO 5-2350-262-35-1

f.

Clean, prime, and paint raw area with suitable CARC prime and finish paint per TB 43-0209.

1.5

SECTION IV. REMOVAL PROCEDURES FOR DRY POWDER (NEW

PRODUCTION VEHICLE SERIAL NUMBERS 574 THROUGH 625)

NOTE

Pay attention to all Notes, Cautions, and Warnings per TM 5-2350-262-20-1, Fixed Dry

Powder Fire Extinguisher Hoses and Fittings Replacement (New Production) and TM 5-2350-

262-20-2, Muffler Shields Replacement.

a.

Remove dry powder fire extinguisher hoses and fittings per TM 5-2350-262-20-1. Remove and discard

four nozzle brackets, nozzles, elbows, and hoses.

b.

Remove dry powder fire extinguisher control valve and cable per TM 5-2350-262-20-1 and TM 5-2350-262-20-

2.

c.

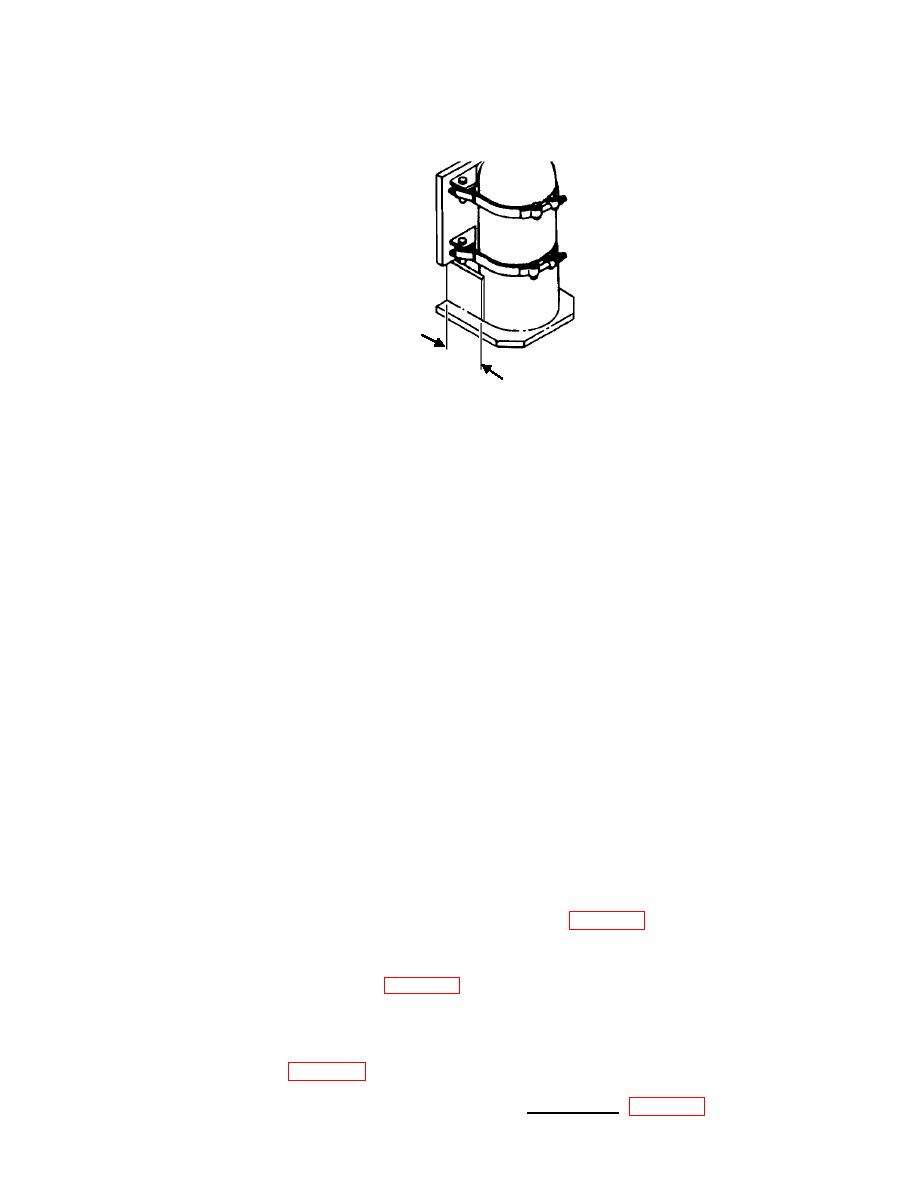

Remove dry powder fire extinguisher cylinder and clamps per TM 5-2350-262-20-1.

d.

If in like-new condition, re-use dry powder bottles Part Number 14607. Bottles date-stamped five years or

older must be static tested by qualified service facility before reuse is authorized.

SECTION V. NOZZLE INSTALLATION PROCEDURES FOR LEFT SIDE (ALL

VEHICLES)

NOTE

Steps a through f below apply to Figure 3-2.

a. Using suitable machinist's ruler, measure, mark, and center punch, for drilling and tapping four holes for

two brackets (10780) on left side (Figure 3-2).

b. Drill 4 x .25 x 20-UNC-2B holes .375 inch deep only and bottom end tap holes, ensuring maximum thread

depth of .375 inch.

c.

Install two brackets (Figure 3-2) with four washers (MS27183-49) and screws (B1821BH025C050N).

d. Install one 90 elbow (2102-8-8) and nozzle (10250) at LOCATION D (Figure 3-2). Using suitable

machinist's protractor and straight edge, direct 90 elbow towards engine with 25 angle down from

horizontal.