TM 5-3800-205-23-1

TORQUE LIMITS

SCOPE

This work package lists standard torque values and provides general information for applying torque. Special torque val-

ues and tightening sequences are indicated in the maintenance procedures for applicable components.

GENERAL

1.

Always use the torque values listed in Tables 1 and 2 when the maintenance procedure does not give a specific torque

value.

a.

Table 1 provides torque limits for SAE standard fasteners.

b.

Table 2 provides torque limits for metric fasteners.

Unless otherwise indicated, standard torque tolerance shall be 10%.

2.

3.

Torque values listed are based on clean, dry threads. Reduce torque by 10% when engine oil is used as a lubricant.

Reduce torque by 20% if new plated capscrews are used.

4.

If the maintenance procedures do not specify a tightening order, use the following guides:

a.

Unless otherwise specified, lubricate threads of fasteners with oil (OE/HDO-10 or OEA).

b.

When tightening fasteners above 30 lb-ft (41 Nm), use the torque pattern but only tighten to 70 percent of final

value (multiply final value by 0.7). Repeat pattern un6til final value is reached.

c.

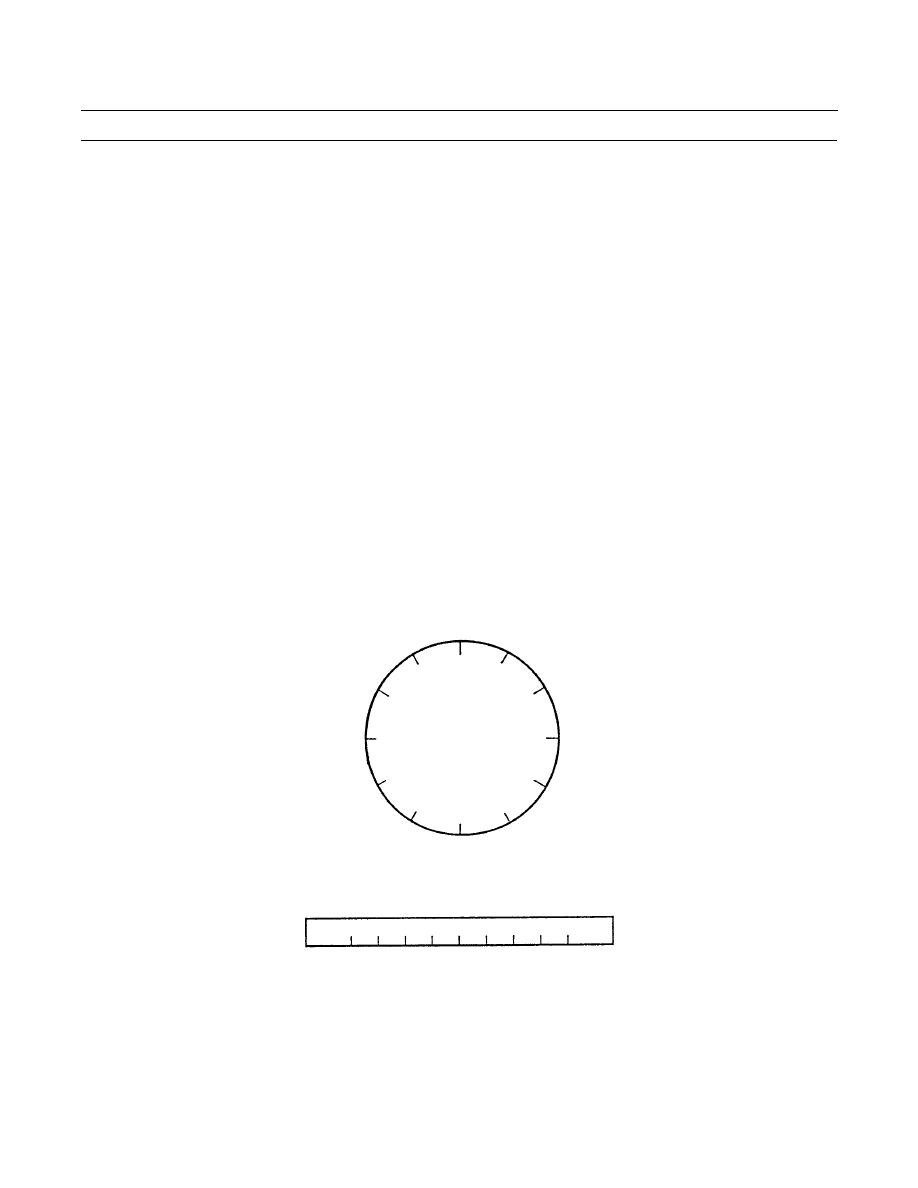

Tighten circular patterns using circular torque pattern and tighten straight patterns using straight torque pattern.

1

8

5

12

10

4

3

11

9

6

7

2

CIRCLULAR TORQUE PATTERN

8

531246

9

7

STRAIGHT TORQUE PATTERN

CAUTION

If replacement capscrews are of higher grade than originally supplied, use torque specifications for the orig-

inal. This will prevent equipment damage due to overtorquing.