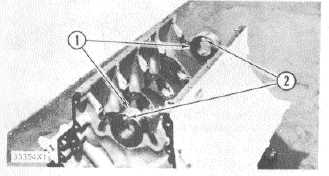

BASIC BLOCK

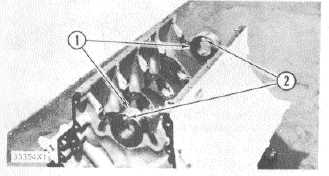

Place I P2344 Centering Rings ( 1), with oiler (2)

up, at each end of’ block. If an end bore is distorted, use

the next good bore.

NOTE: There must be two good bores for locating

centering rings.

CENTERING RINGS IN BLOCK

1. 1P2344 Centering Rings. 2. Oiler.

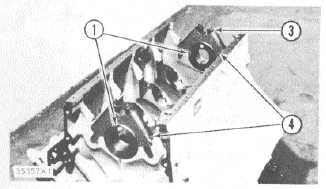

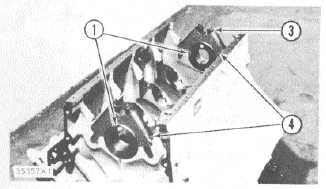

Place original bearing caps (4) over the centering

rings (1). Tighten bolts (3) hand tight.

CENTERING RINGS INSTALLED

1. 1P2344 Centering Rings. 3. Bolts (four). 4.

Bearing caps.

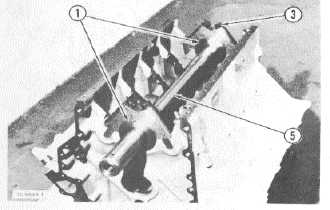

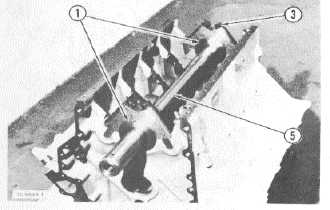

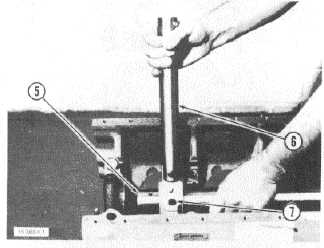

BORING BAR INSTALLED

1. 1 P2344 Centering Rings. 3. Bolts (four). 5.

1P2352

Boring

Bar.

Oil boring bar (5) and insert it through

centering rings (1). Tighten bolts (3) to a minimum

of 20 lb. ft. (25 N. m) and a maximum of 50 lb. ft.

(70 N. m) while spinning bearing bar (5) to check for

binding. Centering rings (I) must be seated in

boring saddles after

tightening.

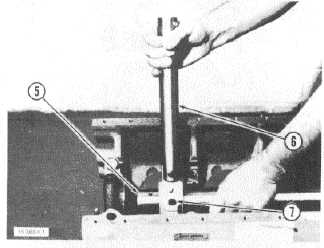

Slide boring bar (5) out of one end of block

and install bearing assemblies (6) on boring bar (5).

Slide boring bar (5) back through centering ring.

Adjust bearing by tightening bolt (7) until bar begins

to bind, then back off until boring bar (5) spins

easily.

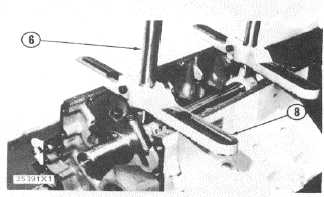

INSTALLING BEARING ASSEMBLIES

5. 1P2352 Boring Bar. 6. 1P2373 Bearing

assembly (two). 7. Bolt.

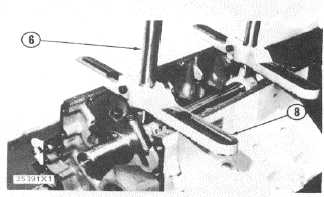

Install bridge assemblies (8) over bearing

assemblies (6). Position bridge assemblies (8) on

block as shown with thicker portion up.

NOTE: Bridge assemblies must be on block as

shown for tool holder clearance at each bore.

BRIDGE ASSEMBLIES INSTALLED

6. 1P2373 Bearing Assembly (two). 8. 1P2343

Bridge Assembly (two)

3-375

. TM 5-3805-260-24

BASIC BLOCK