TM 5-3805-260-24

CHECKING ROTOR TIP CLEARANCE

CRANKSHAFT

Reconditioning of the crankshaft can be done by

grinding the "journals" (bearing surface on the crankshaft

for the connecting rod bearings and main bearings) .010

in. (0.25 mm), .020 in. (0.51 mm) or .050 in. (1.27 mm)

’undersize" (smaller than the original size).

The diameter of the "journals’ for the connecting rod

bearings is 2.7496 .0006 in. (69.840

0.015 mm). The

diameter of the "journals" for the main bearings is 3.4995

.0006 in. (88.887 0.015 mm). The minimum

permissible diameter of the "journals" for the connecting

rod is 2.7486 in. (69.814 mm). The minimum permissible

diameter of the "journals" for the main bearings is 3.4985

in. (88.862 mm). Measure each "journal" in several

places around the diameter to find the maximum wear

point. If the diameter of any "journal" is smaller than the

minimum permissible diameter, grind all of the "journals."

Before grinding a crankshaft, check the crankshaft for

being straight. To check a crankshaft for being straight,

support each end main bearing "journal" in V-blocks.

Using a dial indicator, position the indicator at the zero

reading then measure the total indicator reading at the

other three main bearing "journals." The maximum total

indicator reading is .008 in. (0.20 mm) at the center main

bearing "journal" and .004 in. (0.10 mm) at the other two

main bearing "journals." If total indicator reading is more

than that given but less than .030 in. (0.76 mm) the

crankshaft can be "straightened" (made straight). Before

"straightening"

(making

straight)

a

crankshaft

get

temperature of the crankshaft to 400°F (204°C). For the

specifications for grinding a crankshaft, see the topic

CRANKSHAFT GRINDING SPECIFICATIONS.

With the crankshaft installed in the cylinder block,

check the end play for the crankshaft. End play for the

crankshaft is .003 to .010 in. (0.08 to 0.25 mm).

Maximum permissible end play for the crankshaft is .014

in. (0.36 mm).

NOTE: If end play for the crankshaft is more than the

maximum permissible end play, check the crankshaft

thrust bearing.

CRANKSHAFT GRINDING SPECIFICATIONS

The dimensions and finish for grinding crankshafts

are as follows:

Diameter (A) for connecting rod bearing journals is;

.010 in. (0.25 mm)

Undersize ................................2.7396 + .0006 in.

(69.586 + 0.015 mm)

.020 in. (0.51 mm)

Undersize ................................ 2.7296 .0006 in.

(69.332 0.015 mm)

.050 in. (1.27 mm)

Undersize ................................ 2.6996 .0006 in.

(68.570 + 0.015 mm)

Surface finish must be 10 micro inches (0.25

micrometers) or less.

Radius (B) must be . 100 .010 in. (2.54 0.25 mm).

Surface finish must be 63 micro inches (1.6

micrometers) or less.

The radius must blend smoothly with the newly machined

journals.

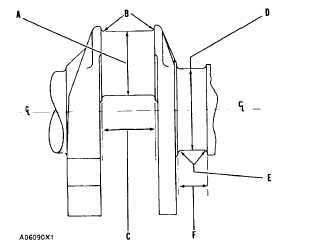

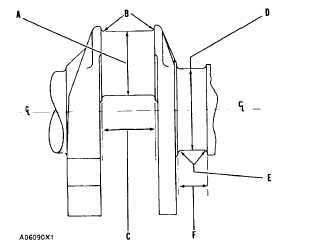

DIMENSIONS FOR GRINDING

A. Diameter of connecting rod bearing journals. B.

Radius on connecting rod bearing journals. C. Width

to grind journals for the connecting rods. D.

Diameter of main bearing journals. E. Radius on

main bearing journals. F. Width to grind journals for

the main bearings.

Width (C) is 2.314 .003 in. (58.77 0.08 mm)

Diameter (D) for main bearing journals is:

.010 in. (0.25 mm)

Undersize ................................ 3.4895 .0006 in.

(88.633 0.015 mm)

.020 in. (0.51 mm)

Undersize ................................ 3.4795 .0006 in.

(88.379 0.015 mm)

.050 in. (1.27 mm)

Undersize ................................ 3.4495 .0006 in.

(87.617 0.015 mm)

3-386