TM 5-3805-260-24

CRANKSHAFT

Surface

finish

must

be

10

micro

inches

(0.25

micrometers) or less.

Radius (E) must be .095 .010 in. (2.41 0.25 mm)

Surface finish must be 63 micro inches (1.6

micrometers) or less.

The radius must blend smoothly with the newly

machined journals.

Width (F) is 1.258 .002 in. (31.95 0.05 mm) for

number 4 main bearing journal. Surface finish on the

thrust faces of the number 4 main must be 18 micro

inches (0.45 micrometers) or less. Width (F) is 1.268 +

.020 - .010 in. (32.21 + 0.51 - 0.25 mm) for number 2, 3,

and 5 main bearing journals.

There is no width (F) for number 1 main bearing

journal.

When grinding a crankshaft, no material can be

removed from the crankshaft webs or counterweights.

CRANKSHAFT GEAR REMOVAL

Remove the gear using an 8B7548 Push Puller,

8B7551 Bearing Pulling Attachment, 8B75621 Step

Plate, and 8H684 Ratchet Box Wrench.

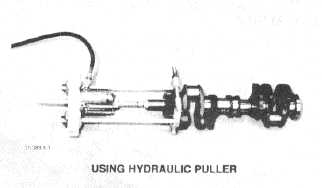

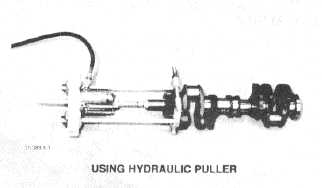

PULLING CRANKSHAFT GEAR

The IP820 Hydraulic Puller Group can also be used to

pull gear from crankshaft. Tools required are IP820

Hydraulic

Puller

Group,

8B7551

Bearing

Pulling

Attachment, 8B7549 Puller legs (two), 8B7561 Step

Plate, 3H465 Plate (four), IB4207 Nut (two), and 5P3100

Pump Group.

USING HYDRAULIC PULLER

CRANKSHAFT GEAR INSTALLATION

1. Install the key in keyway of crankshaft. Remove all

burrs from key and keyway inside of crankshaft gear.

2. Heat gear to 500°F (260°C) maximum.

3. Install gear on crankshaft with timing mark on gear

facing front of crankshaft.

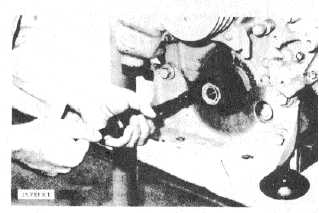

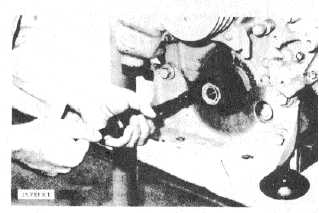

CRANKSHAFT FRONT OIL SEAL REMOVAL

Remote the crankshaft front pulley. Use the 1P3075

Puller Group to remove the crankshaft front oil seal.

REMOVING FRONT OIL SEAL

(Typical Example)

3-387