TM 5-3800-205-10-1

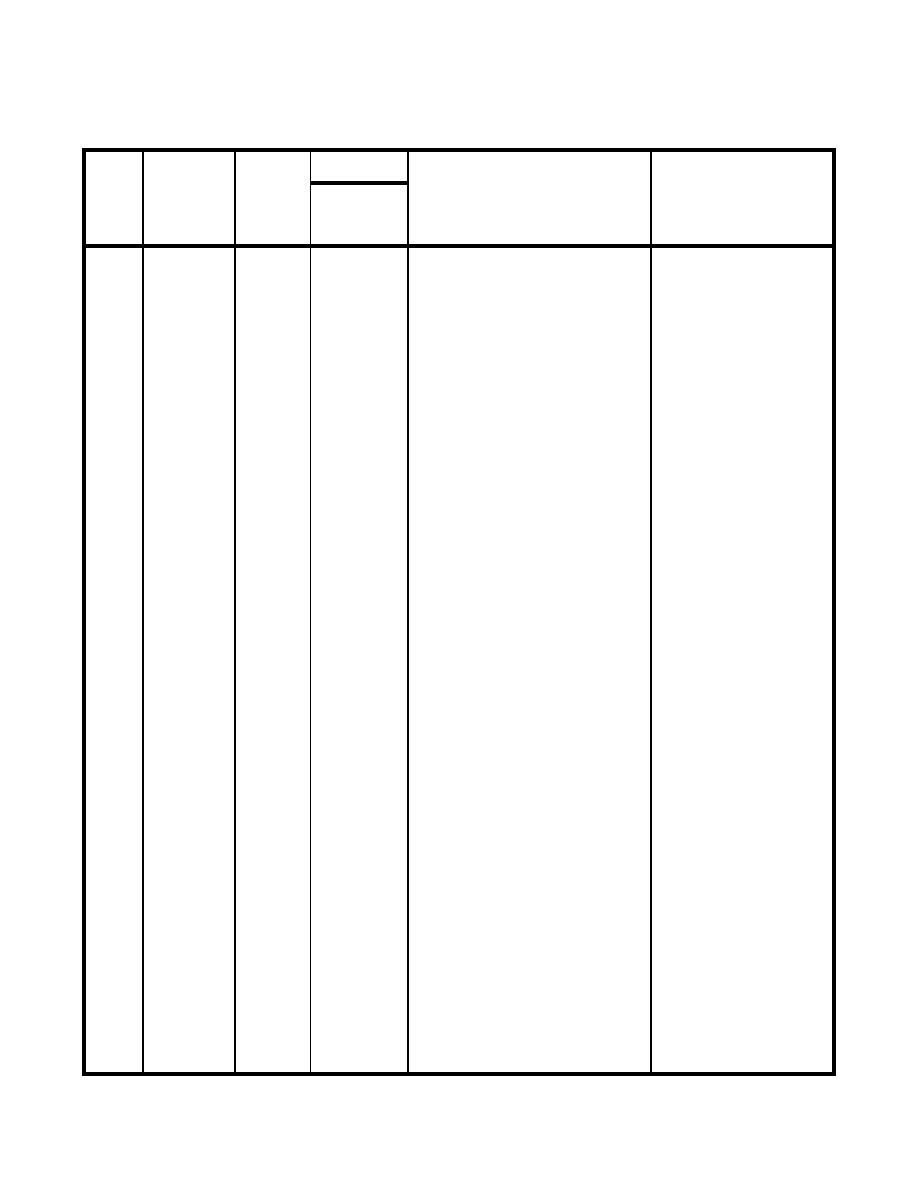

Table 1. Preventive Maintenance Checks and

Services (PMCS) for 613CS Scraper - Continued.

LOCATION

ITEM TO

CHECK/

ITEM

MAN-

NOT FULLY MISSION

SERVICE

NO.

INTERVAL

HOURS

PROCEDURE

CAPABLE IF:

b. On both sides of hitch, check b. Class III hydraulic fluid

42

After

Hitch Area

leaks are evident. Any

(Con't)

hydraulic

steering

cylinders,

fuel leaks are evident.

hydraulic and fuel hoses, lines, and

Any breaks are noted in

fittings, and air and bare electrical

air and bare electrical

wires for damage or signs of leaking

wires. Loose or missing

and secure mounting.

mounting hardware is

noted.

c. Visually check area for any obstruc-

tions between moving components

of hitch. Remove obstructions and

check for damage.

d. Check for damage to parking brake d. Parking brake actuator or

actuator, actuator rod boot, and air

hose is damaged.

hose.

43

After

Drive Line

a. Visually check differential assembly a. Class III oil leaks are evi-

for signs of oil leakage.

dent.

b. Check lower drive shaft for dam- b. Damage

that

would

aged or missing parts.

impair operation is evi-

dent.

Draft Frame, a. Check draft frame for cracks, dam- a. Cracks, damage or distor-

44

After

age or distortion.

tion are noted.

Scraper

Bowl, Eleva-

tor, and

Ejector

b. Check hydraulic lines and hoses b. Class III hydraulic fluid

leaks are evident. Loose

along draft frame for damage or

or missing mounting

signs of leaking and secure mount-

hardware is noted.

ing.

c. Check for damage to quick discon- c. Class III hydraulic fluid

nect fittings. Check for condition

leaks are evident

and presence of dust caps.

d. Check fuel lines and air line along d. Any air or fuel leaks are

evident. Loose or missing

front of scraper bowl for damage or

mounting hardware or

signs of leaking and secure mount-

damage is evident.

ing.

e. Check bare electrical wires and con- e. Bare electrical wires or

nectors for damage and secure

connectors are damaged.

mounting.

0014 00-29