TM 5-3800-205-10-1

RAIL TRANSPORT - CONTINUED

0021 00

RETURN MACHINE TO OPERATIONAL CONFIGURATION - CONTINUED

5.

OCONUS ONLY: Return elevator to work configuration:

WARNING

If operating machine without ROPS/FOPS, drive with extreme caution, at low idle, and in 1st gear or reverse

ONLY. Machine has no rollover/falling object protection without ROPS/FOPS. Failure to follow this warn-

ing may cause injury or death to personnel or damage to equipment.

6.

NOTE: Machine is now drivable. However, until ROPS/FOPS is installed, it should be operated only with extreme cau-

tion, at low idle and in 1st gear or reverse ONLY. As required, move machine to a new location to complete machine

assembly.

7.

Return elevator to work configuration:

WARNING

Scraper floor and floor rollers are in motion when ejector is in motion. Stand clear of scraper bowl to avoid

injury to personnel.

a.

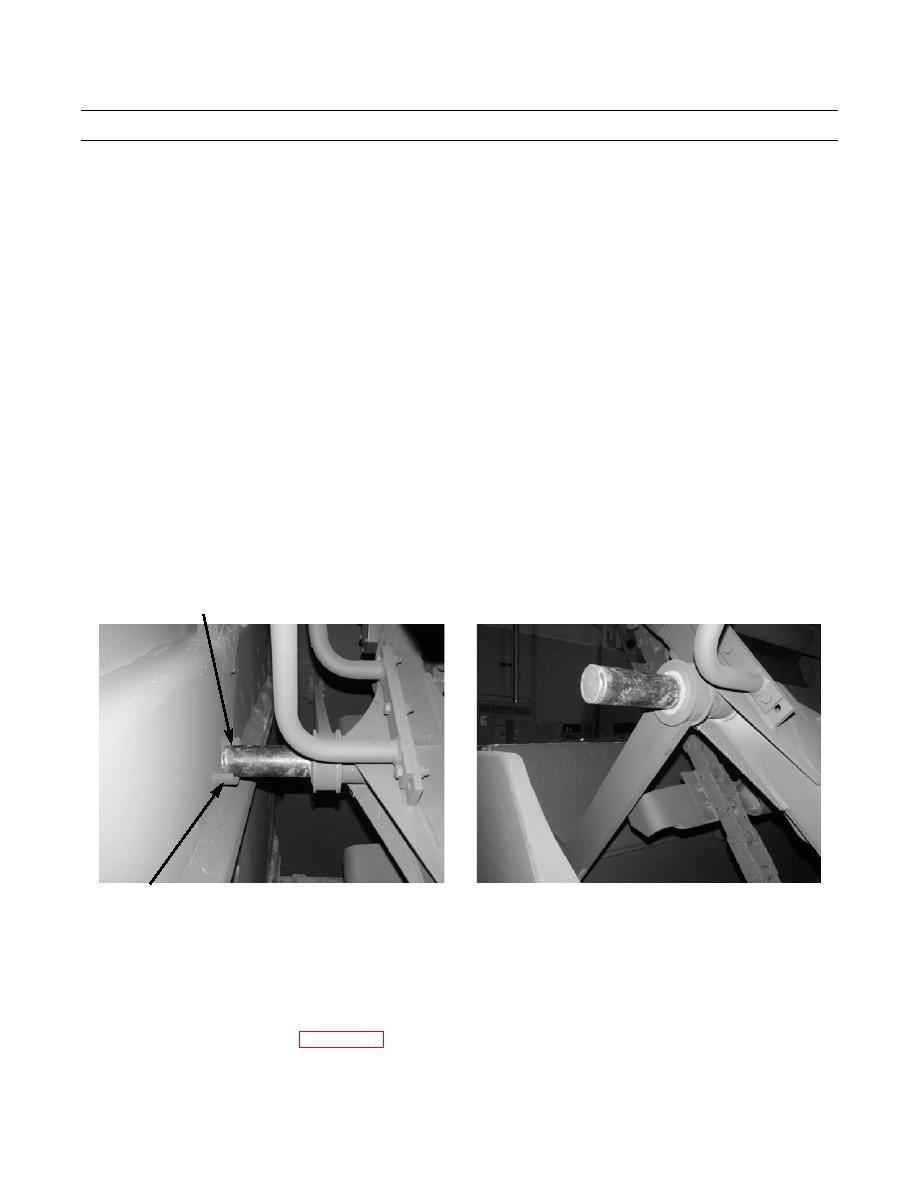

Start engine and raise elevator by moving ejector forward until elevator shafts are free of hangers.

ELEVATOR SHAFT

390-1077

ELEVATOR RAISED

ELEVATOR LOWERED

HANGER

b.

Install elevator hangers:

(1)

Remove hangers from BII toolbox on rear deck of scraper.

NOTE

GAA grease (Item 10, WP 0026 00) coated on elevator shafts will make hangers easier to install.

(2)

Position large end of each hanger on elevator shaft.

0021 00-34