TM 5-3800-205-23-1

TROUBLESHOOTING PROCEDURES - CONTINUED

0007 00

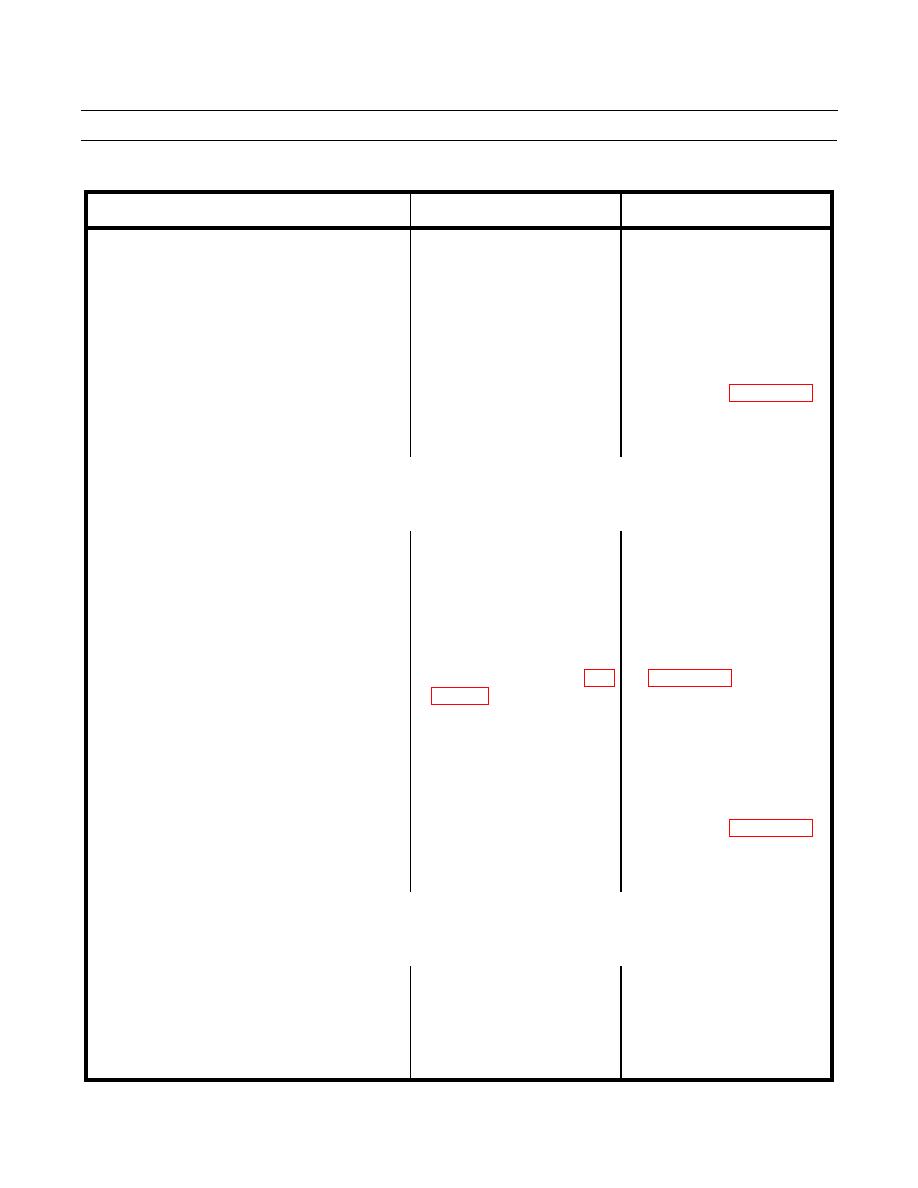

Table 7. Scraper System Troubleshooting Procedures - Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

a. Repair any leaks if required.

2. Bowl Drifts After Control Lever is Released or

2. Check

bowl

hydraulic

Centered- Continued.

cylinder(s)

for

external

leakage.

b. If cylinder(s) are damaged,

replace cylinder(s) (TM 5-

3800-05-23-2).

3. Ejector Control Lever Binds.

1. Check for bent or damaged

a. If lever is bent or damaged,

lever.

replace lever (WP 0114 00).

b. If lever is okay, go to test step

2.

WARNING

Park machine on level ground, stop engine, and lower bowl/water tank to prevent injury to operator

and/or severe damage to machine.

a. Clean debris from control

2. Check bowl/ejector main

valve linkage.

control valve, inboard of right

fender for buildup of debris.

b. If problem still exists, go to

test step b.

a. Adjust relief valve setting

3. Perform Main Control Valve

b. If problem still exists after

adjustment,

notify

DS

Maintenance to replace main

control valve.

4. Elevator Control Lever Binds.

1. Check for bent or damaged

a. If lever is bent or damaged,

lever.

replace lever (WP 0114 00).

b. If lever is okay, go to test step

2.

WARNING

Park machine on level ground, stop engine, and lower bowl/water tank to prevent injury to operator

and/or severe damage to machine.

a. Clean debris from control

2. Check elevator main control

valve linkage.

valve, inboard of left fender,

for buildup of debris.

b. If problem still exists, go to

test step 3.