TM 5-3800-205-23-1

TROUBLESHOOTING PROCEDURES - CONTINUED

0007 00

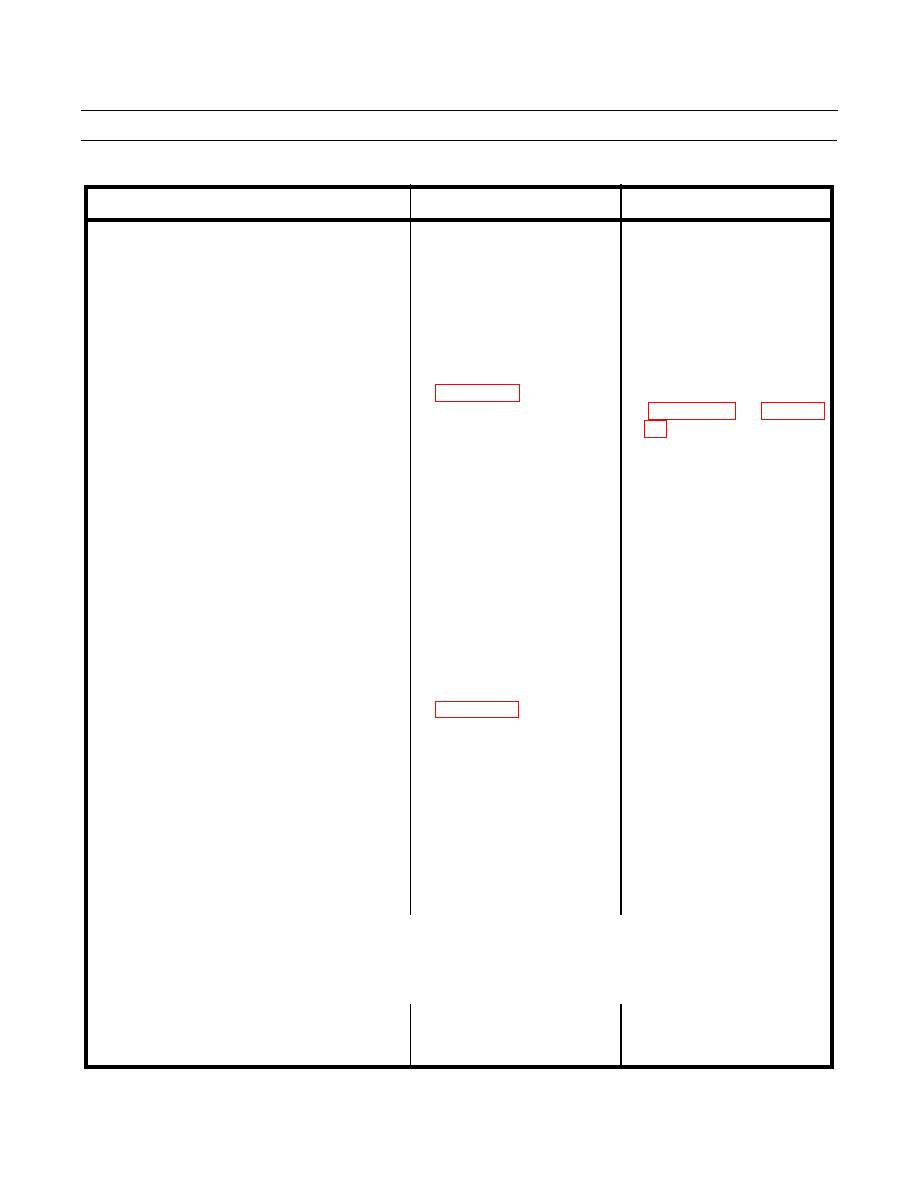

Table 7. Scraper System Troubleshooting Procedures - Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

7. Oil Temperature is Too Hot - Continued

2. Check hydraulic oil level.

a. If oil level is low, fill to

correct level (TM 5-3800-

205-10-1 or TM 5-3800-205-

10-2).

b. If problem still exists, go to

test step 3.

a. If viscosity of hydraulic oil is

3. Check hydraulic oil viscosity

not to specification, replace

in accordance with PMCS

oil with specified type oil

b. If problem still exists, go to

test step 4.

4. Check that load on system is

a. Reduce load.

not too high.

b. If problem still exists, go to

test step 5.

5. Check for hydraulic oil

a. If any leakage is found, notify

leakage at piston seals on

DS Maintenance to replace

steering cylinder(s).

steering cylinder(s).

b. If problem still exists, go to

test step 6.

6. Perform Steering System Test

a. If low pressure output is

indicated,

notify

DS

Maintenance to replace

steering control valve.

b. If problem still exists, go to

test step 7.

7. Check for air in system.

If air is found, notify DS

Maintenance to replace steering

vane pump.

8. Travel Time of Bowl Cylinders is Slow.

NOTE

To verify travel time of bowl cylinders, lower bowl to ground. Run engine at high idle RPM. Use a

stopwatch to verify time required to fully lift bowl. Time required to lift bowl from ground is approxi-

mately 4 seconds.

a. Clean any

debris

from

1. Check

bowl

hydraulic

cylinder(s).

cylinders for any buildup of

debris.