TM 5-3800-205-23-2

EJECTOR CLEARANCE ADJUSTMENT

THIS WORK PACKAGE COVERS

Adjustment

INITIAL SETUP

Equipment Condition

Maintenance Level

Machine parked on hard, level surface (TM 5-3800-

Unit

205-10-1)

Tools and Special Tools

Ejector positioned to rear (TM 5-3800-205-10-1)

Tool kit, general mechanic's (Item 33, WP 0048 00)

Scraper bowl lowered to ground (TM 5-3800-205-

10-1)

Personnel Required

Parking brake applied (TM 5-3800-205-10-1)

Two

Wheels chocked (TM 5-3800-205-10-1)

Battery disconnect switch in off position (TM 5-

3800-205-10-1)

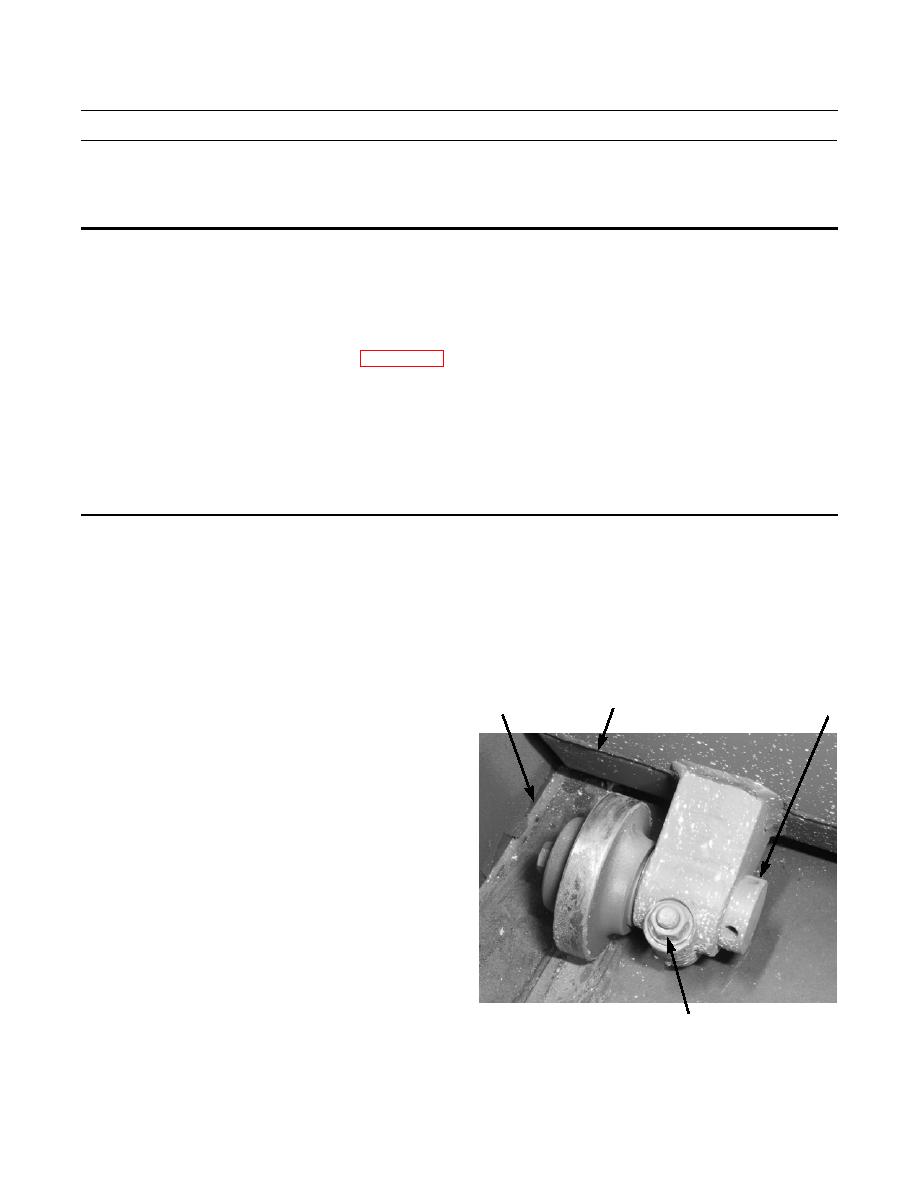

ADJUSTMENT

NOTE

When roller shaft is rotated, roller moves up or down.

1.

Measure clearance between bottom edge of ejector (2) and scraper floor (1). Clearance must be 0.03-0.25 in. (0.8-6.4

mm). If clearance is not as specified, loosen locknut (4).

2.

Insert a 0.44 in. (11 mm) diameter rod in holes of

2

1

3

roller shaft (3) to move bottom edge of ejector (1).

3.

Once correct clearance is obtained, tighten locknut (4).

390-1775

END OF WORK PACKAGE

4