TM 5-3805-260-24

adds to the pump oil in line (10) to elevator control valve

(12). With the engine running at high rpm and the valve

spool in control valve (12) in FORWARD position (C), the

oil from pump (22) goes through line (7) to run elevator

hydraulic motor (1) forward at high speed. The oil from

the elevator motor goes through line (8), control valve

(12) and through return oil line (13) into filter and tank

(19).

Move the elevator speed lever to the LOW position and

the valve spool in elevator speed valve (6) moves to

LOW SPEED position (L). Now, the oil from the cover

end of pump (22) goes through speed valve (6) and goes

into return oil line (13) to the tank. With only oil from one

section of pump (22) to elevator motor (1), the elevator

runs at a slow speed.

The elevator control lever must be moved to the HOLD

position to move the elevator valve spool to HOLD

position (B). With the valve spool in HOLD position, the

oil from pump (22) goes through control valve (12),

through return oil line (13) into filter and tank (19).

Elevator Reverse (No Illustration)

The elevator control lever is held in the REVERSE

position by the detent balls in elevator control valve (12).

With the valve spool in REVERSE position (A), the oil

from pump (22) goes through control valve ( 12) and

through line (8) to elevator motor (1) to run the elevator

in reverse. The oil from the elevator goes through line

(7), through control valve (12) and through return oil line

(13) into the filter and tank (19). The reverse speed of

the elevator is controlled by the rpm of the engine and

the position of the elevator speed lever connected to the

valve spool in elevator speed valve (6). HIGH SPEED

position (H) lets the oil from the cover end section of

pump (22) add to the oil from the drive end section of the

pump in line ( 10) to the elevator motor. The speed valve

stem in LOW SPEED position (L) lets the oil from the

cover end section of pump (22) go through return oil line

(13) to the tank. Now, only the oil from the drive end

section of the pump goes through line (10) and to the

elevator motor.

Move the control lever to the HOLD position. This moves

the elevator valve spool to HOLD position (B) and stops

the elevator.

ELEVATOR VALVES

Control Valve

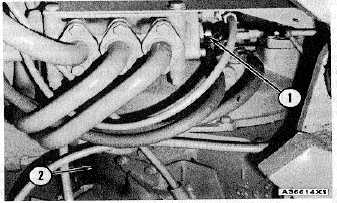

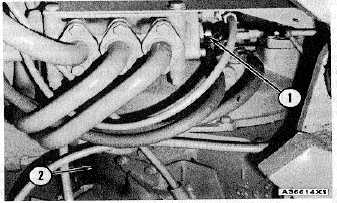

The location of the elevator control valve is just in front of

transmission (2), near the left side of the machine. The

flexible cable from the control lever goes under the

scraper hitch and is connected to valve spool (I) in the

elevator control valve.

ELEVATOR CONTROL VALVE

1. Valve spool (in control valve). 2. Transmission.

Detent balls, in the control valve, keep valve spool (1) in

any of the three positions for the valve spool. When the

valve spool is held in FORWARD position (C), the oil

from the pump goes in through inlet (6), opens check

valve (7),- goes through the check valve and through

outlet (4) that connects with an oil line to the elevator

hydraulic motor.

ELEVATOR CONTROL VALVE (HOLD POSITION)

1. Valve stem. 3. Outlet to tank. 4. Outlet to motor

(for reverse). 5. Outlet to motor (for forward). 6. Inlet

from pump. 7. Check valve. A. REVERSE position. B.

HOLD position. C. FORWARD position.

With valve spool (1) in HOLD position (B), the pump oil

through inlet (6) does not get any pressure to open

check valve (7) because the oil goes out through outlet

(3) and to the tank. The spring in check valve (7) keeps it

closed, when there is no pump oil pressure in the control

valve, and the oil in the lines to the elevator motor is

stopped. The hydraulic motor can not be turned when oil

is stopped in the lines to the motor.

With valve spool (1) in REVERSE position (A), the pump

oil through inlet (6) opens check valve (7) and then goes

through outlet (5) that connects with an oil line to the

elevator motor.

4-20