TM 5-3800-205-10-1

TROUBLESHOOTING PROCEDURES - CONTINUED

0012 00

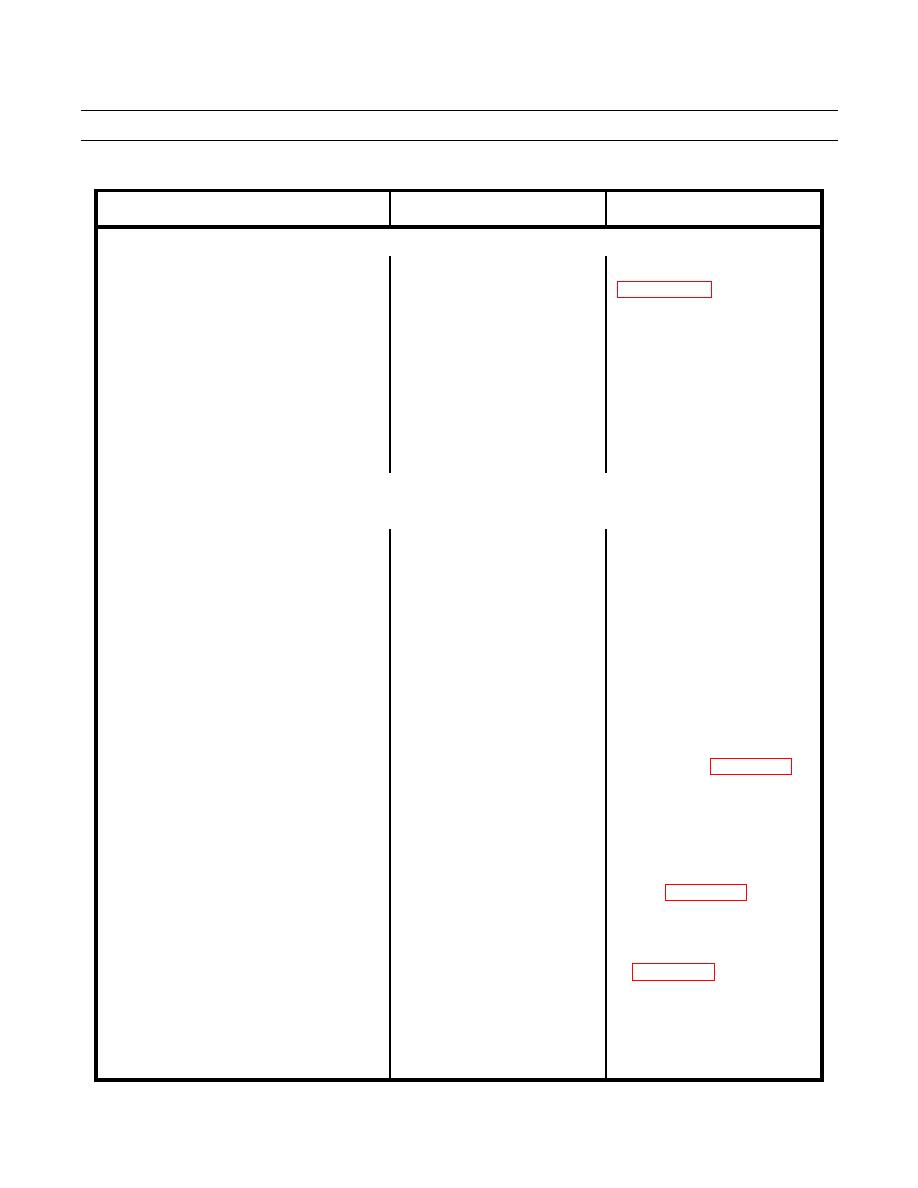

Table 1. Troubleshooting Procedures - Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

ENGINE - CONTINUED

4.

Engine Does Not Idle Properly.

Check air filter service indicator.

If indicator is red, clean air filter

problem still exists, notify Unit

Maintenance.

5.

Engine Fails to Crank When Key Start

1. Check position of battery

1. Place battery disconnect

Switch is Turned to Start.

disconnect switch.

switch to ON. If problem still

exists, go to test step 2.

2. Check position of transmission

2. Place transmission shift lever

shift lever.

in N (Neutral). If problem still

exists, go to test step 3.

NOTE

A thirty (30) minute cool down time may be required before circuit breaker can be reset.

3. Check that key start switch

3. Reset circuit breaker. If

circuit breaker is not tripped.

problem still exists, go to test

step 4.

4. Check for dirty, loose or

4. Clean dirty cables. Tighten

damaged battery cables.

loose connections. If cable is

damaged,

notify

Unit

Maintenance.

6.

Engine Starts But Dies.

Check for loose electrical

If connections are okay, notify

connections at engine shutoff

Unit Maintenance.

7.

Engine Starts But Misfires or Runs

Check fuel/water separator for

Open fuel/water separator drain

Rough After Warmup Period.

moisture.

valve and drain (WP 0014 00). If

problem still exists, notify Unit

Maintenance.

8.

Excessive Engine Oil Consumption.

Check for loose oil lines and oil

If oil lines are loose or leaks are

leaks.

found, notify Unit Maintenance.

9.

Excessive Exhaust Smoke (At Normal

1. Check air

filter

service

1. If indicator is red, clean air

Operating Speed).

indicator.

filter (WP 0015 00) and retest.

If problem still exists, go to test

step 2.

2. Check for water in fuel.

2. Drain fuel/water separator

exists,

notify

Unit

Maintenance.