TM 5-3800-205-23-2

ELECTRICAL GENERAL MAINTENANCE INSTRUCTIONS - CONTINUED

0003 00

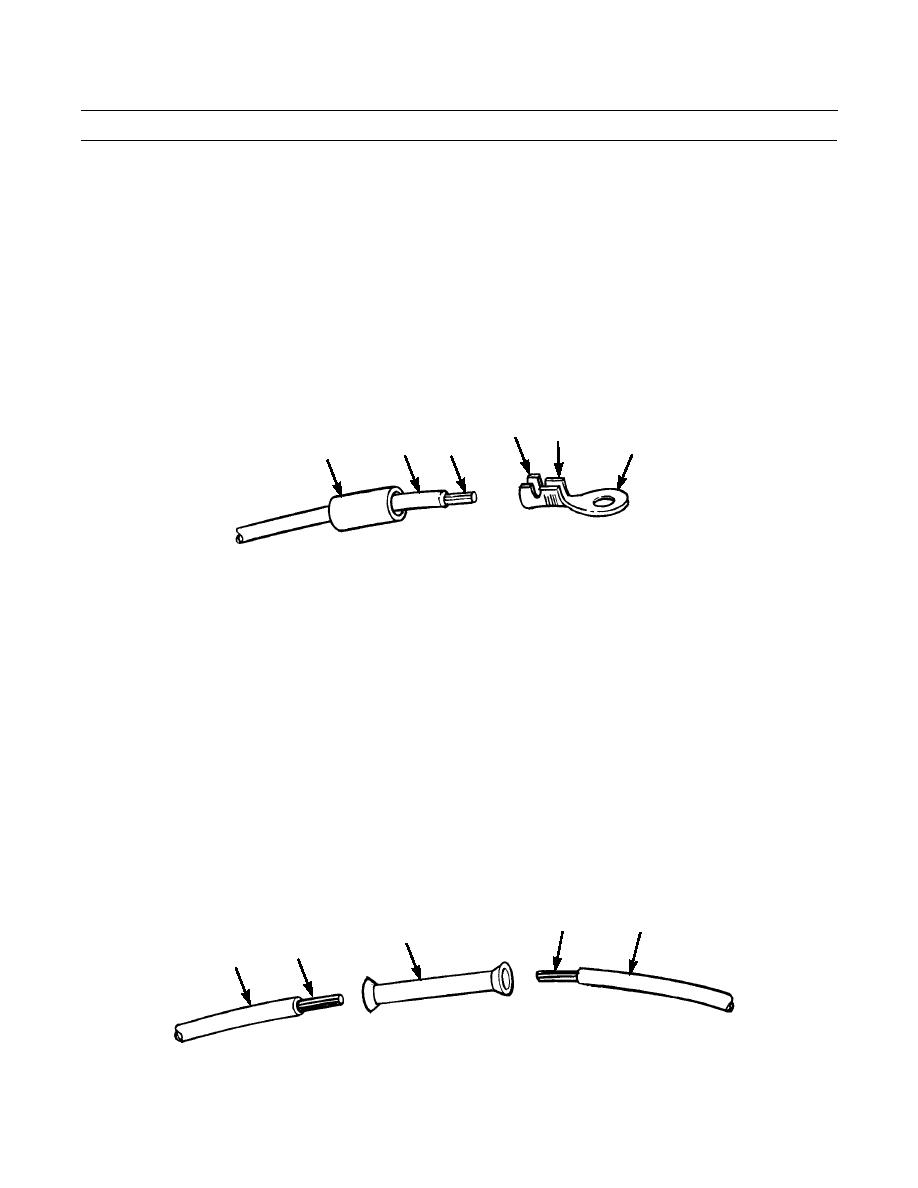

RING TERMINAL REPAIR

1.

Remove ring terminal (38) from wire (34) by cutting through wire just behind heat shrink tubing (33).

2.

Cut heat shrink tubing (33) to length sufficient to cover tabs (36 and 37) of ring terminal (38) and 1/4 in. (6 mm) of wire

(34).

3.

Slide heat shrink tubing (33) back on wire (34).

4.

Using wire stripping tool, strip insulation of wire (34) to expose proper length of metal strands (35).

5.

Using crimping tool, securely crimp tabs (37) of ring terminal (38) over metal strands (35).

6.

Using crimping tool, crimp tabs (36) of ring terminal (38) over insulation of wire (34).

7.

Slide heat shrink tubing (33) over tabs (36 and 37) of ring terminal (38).

8.

Use a heat gun to apply heat to heat shrink tubing (33) until tubing snugly conforms to ring terminal (38) and insulation

of wire (34).

36

37

38

35

34

33

390-1197

SPLICING WIRES

NOTE

The selection of crimping tool and type of splice connectors is optional. High quality splice connectors can

be expected to last the life of the machine.

1.

Inspect each end of wire (39). Trim insulation and metal strands (40) of wire back, as necessary, to ensure integrity of

wire.

2.

Using wire stripping tool, strip each end of wire (39) to expose length of metal strands (40) to suit type of splice connec-

tor (41) used.

NOTE

Perform steps 3 and 4 at each end of splice connector.

3.

Insert metal strands (40) of wire (39) fully into splice connector (41).

4.

Using crimping tool, securely crimp splice connector (41) to metal strands (40) of wire (39).

40

39

41

40

39

390-1198

0003 00-7