TM 5-3805-248-23-2

PISTON AND CONNECTING ROD MAINTENANCE - CONTINUED

0348 00

DISASSEMBLY - CONTINUED

NOTE

Remove piston pin bearing only if inspection indicates replacement is necessary.

7.

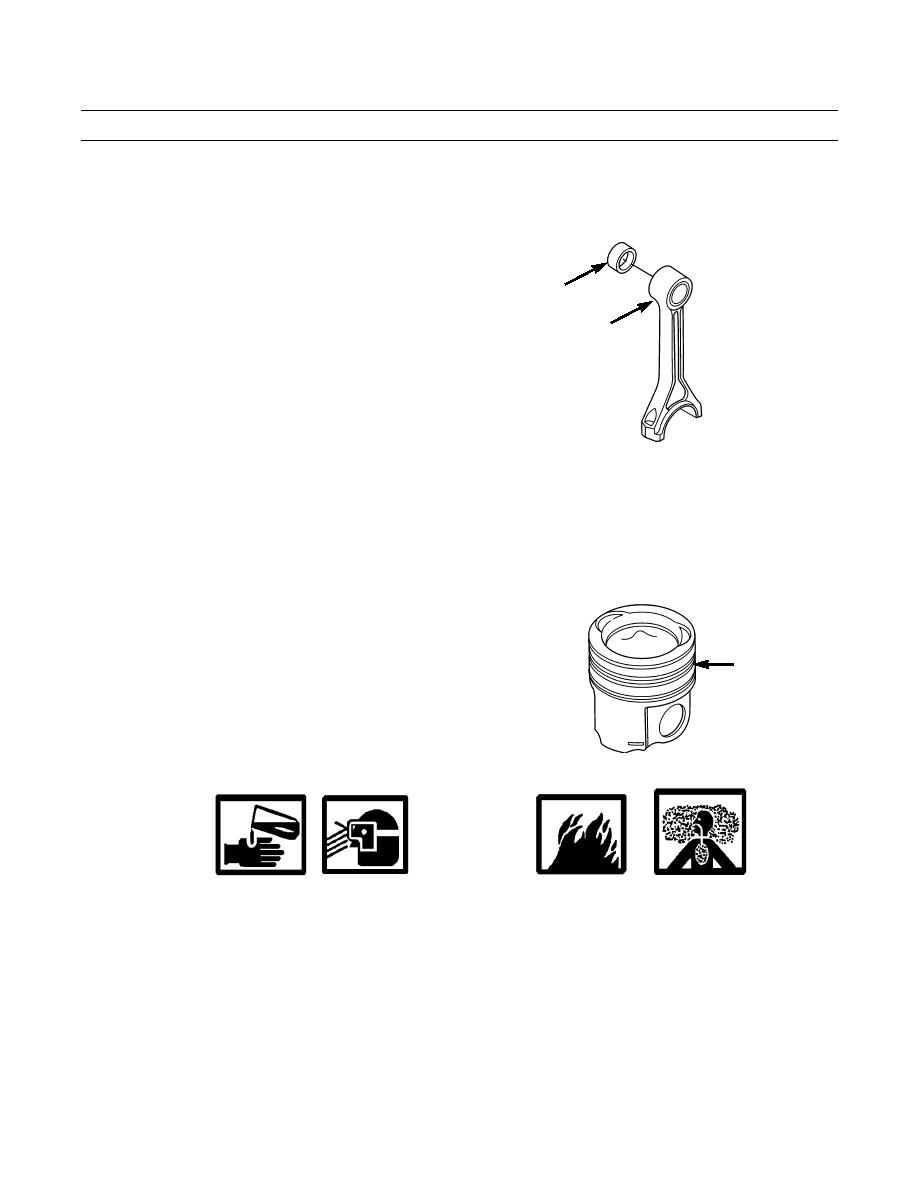

Use press rod to remove pin bearing (12) from con-

necting rod journal (2), if necessary.

12

2

394-1162

CLEANING

NOTE

Repeat steps 1 through 5 for all piston and connecting rod sets. Keep sets separated and tag for identifica-

tion.

1.

Remove carbon from piston (4), being careful not to scratch piston.

2.

Use groove cleaning tool to remove any carbon or res-

idue from piston ring grooves.

3.

Use a small drill or fine wire to remove carbon or resi-

4

due from piston oil hole.

394-1163

WARNING

Solvent cleaning compound MIL-PRF-680 Type III is an environmentally compliant and low toxic

material. However, it may be irritating to the eyes and skin. Use protective gloves and goggles. Use in

well-ventilated areas. Keep away from open flames and other sources of ignition.

Particles blown by compressed air are hazardous. DO NOT exceed 15 psi (103 kPa) nozzle pressure

when drying parts with compressed air. Use a maximum of 30 psi (207 kPa) when cleaning compo-

nents. DO NOT direct compressed air against human skin. Failure to follow this warning may result in

injury or death. Make sure air stream is directed away from user and other personnel in the area. To pre-

vent injury, user must wear protective goggles or face shield.

4.

Clean all parts with solvent.

5.

Dry all parts with compressed air.

0348 00-5