TM 5-3805-248-23-2

PISTON AND CONNECTING ROD MAINTENANCE - CONTINUED

0348 00

INSPECTION - CONTINUED

NOTE

Connecting rod must be heated for instal-

lation of piston pin bearing. Do not use

torch.

16.

Use oven to heat connecting rod (2) to 350-500F

(176-260C).

17.

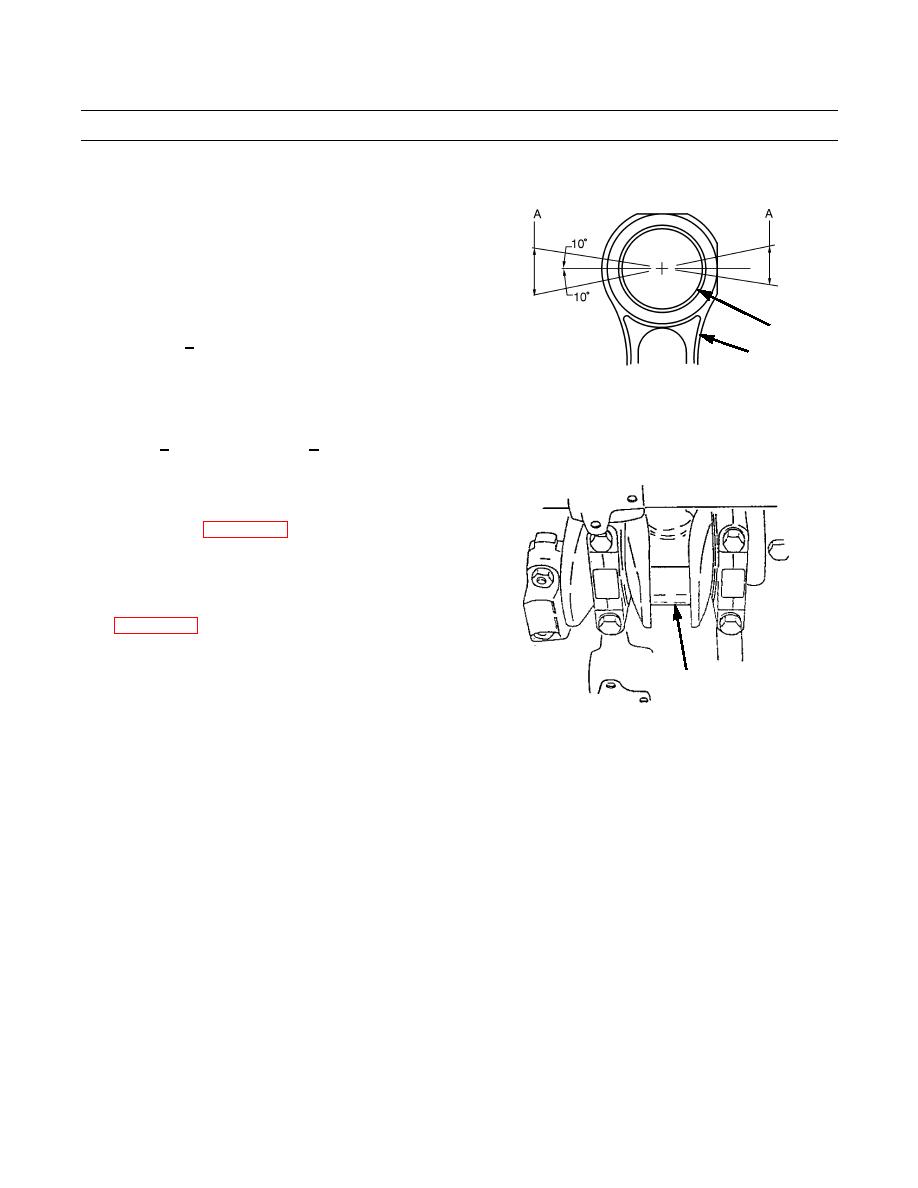

Position new piston pin bearing (12) within areas "A"

12

90 degrees+10 degrees from centerline through bore

2

of connecting rod (2).

394-1167

18.

Use handle and drive plate and press group to install

new pin bearing (12). Align oil holes.

19.

Use boring machine to bore new pin bearing (12) to

2.0012+0.0003 in (50.8304 mm+0.00762 mm).

20.

Use micrometer to measure connecting rod journal

taper from front to rear of journals on crankshaft. If

taper exceeds 0.0008 in. (0.0203 mm), grind crank-

shaft journals (WP 0346 00).

21.

Use micrometer to measure out-of-roundness in con-

necting rod journals (12) on crankshaft. Check 90

degrees from points checked in step 19. If out-of-

roundness exceeds 3.8208 in. (97.0483 mm), refer to

22.

Repeat steps 1 through 21 for the remaining piston and

connecting rod sets.

CONNECTING

ROD JOURNAL

394-1168

0348 00-9