TM 5-3800-205-23-1

CONTAINER REPAIR - CONTINUED

0164 00

REPAIR OF FACE/SKIN DAMAGE TO FIBERGLASS REINFORCED PLASTICS (FRP)

MATERIAL - CONTINUED

10.

Check exterior surface to make certain patch is flush with surrounding panel surface. Remove excess filler paste

before it hardens. Before proceeding to next step, allow resin paste to fully harden for approximately 12 hours.

11.

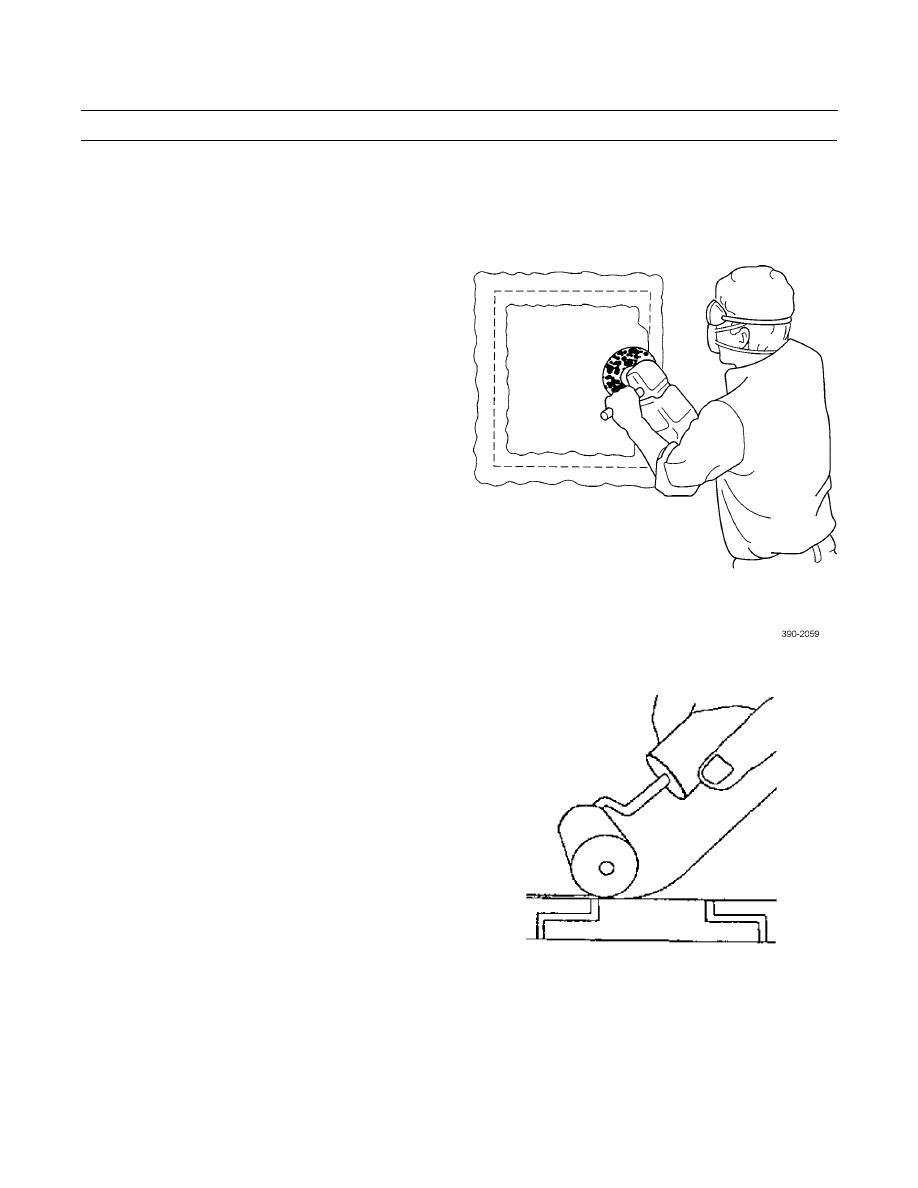

Using disc sander, grind inside surface down to ply-

wood core. Mix sufficient resin and curing agent to

saturate pre-cut glass reinforcement material. Also,

brush coat ground out area. Apply glass reinforce-

ment to area and roll out brush to remove air bub-

bles.

12.

Using disc sander, grind outside surface down to

plywood core to approximately 4 in. (102 mm) wide

around outside joint. Take glass cloth tape, saturated

with resin, and roll out.

13.

Lightly sand joint and wipe clean. Mix a sufficient

amount of surfacing paste and catalyst and apply a

brush coat or use a putty knife. Allow to harden and

sand smooth. Cut sheet of film approximately 1/2 in.

(13 mm) larger around than repair area. Strip off

backing sheet and apply it slowly to surface with a

seam roller to eliminate all bubbles or wrinkles. Roll

outer edges to bond these firmly to panel.

390-1924

0164 00-19