TM 5-3805-248-23-2

CRANKSHAFT MAIN BEARINGS MAINTENANCE - CONTINUED

0347 00

CENTER AND INTERMEDIATE BEARINGS ADJUSTMENT - CONTINUED

7.

Use clean engine oil to lubricate new lower half main bearing (4).

8.

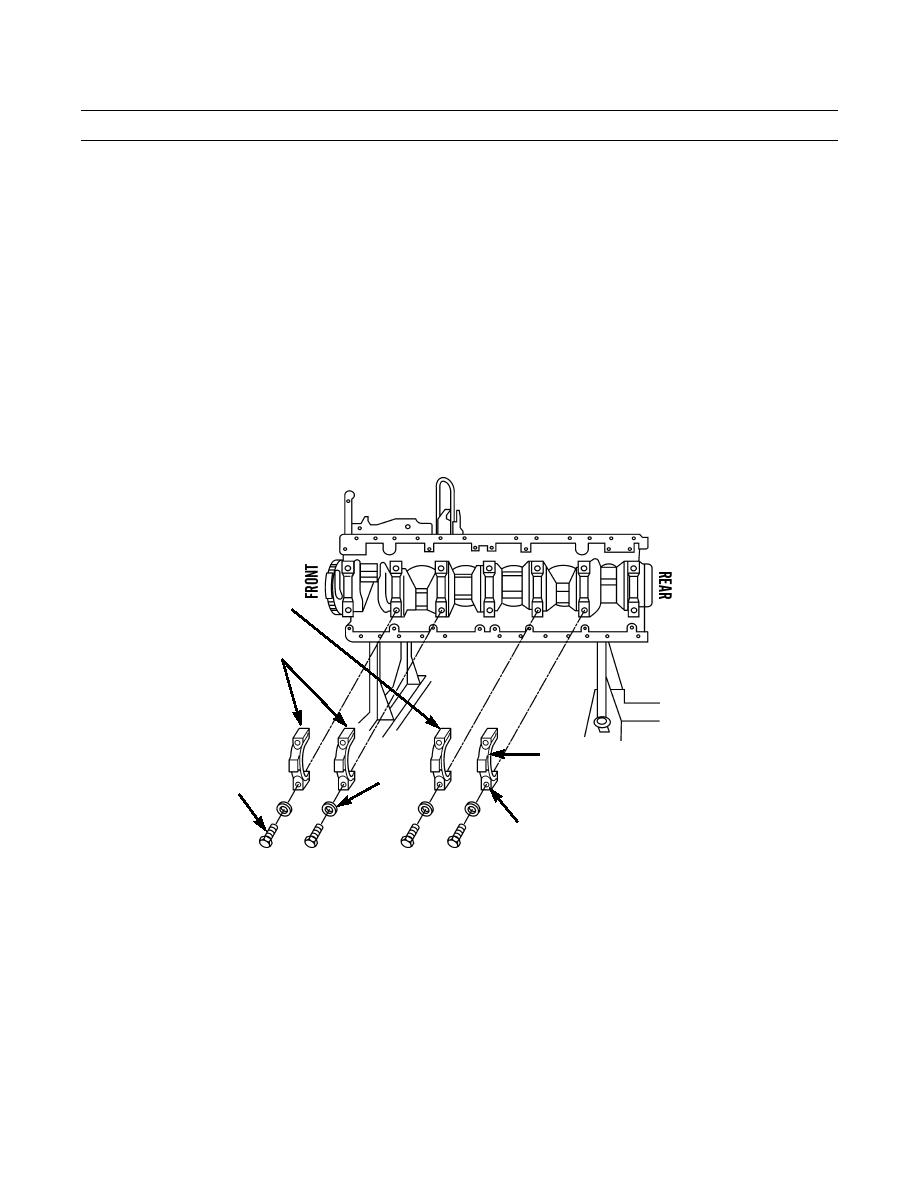

Install new lower half main bearing (4) in bearing cap (3).

9.

Position bearing clearance gage 1-1/2 in. long on surface of new lower half main bearing (4).

CAUTION

Arrow on bottom of bearing caps point to front of engine; number on bearing cap must match bearing num-

ber on side of cylinder block. Failure to follow this procedure could result in damage to equipment.

10.

Position bearing cap (3) assembly and bearing clearance gage under crankshaft journal with arrow on bearing cap point-

ing toward front of engine and holes in bearing cap (3) aligned with holes in cylinder block.

11.

Use clean engine oil to lubricate two bolts (1).

12.

Install and hand-tighten two bolts (1).

13.

Repeat steps 7 through 12 to install four new lower half main bearings (9), bearing caps (8) and eight bolts (6).

3,4

8,9

CLEARANCE

GAGE (HIDDEN)

7

6

8,9

394-1145

0347 00-6