TM 5-3805-260-24

BOWL LIFT CYLINDERS

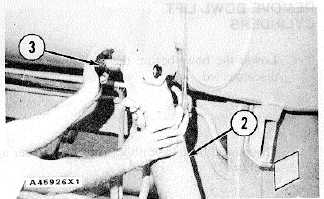

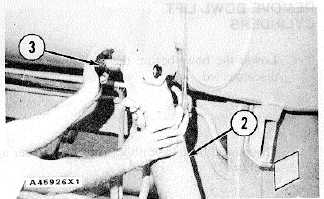

3. Lift the cylinder (2) into position and install pin (3) as

shown.

4. Install the plates and bolts that hold pin (3) and the

rod end pin.

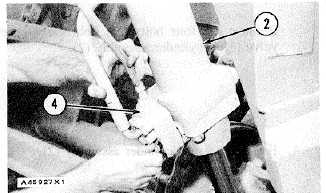

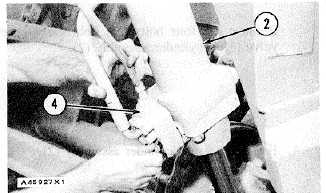

5. Put carry check valve (4) in position on cylinder

assembly (2) and install the four bolts to hold it.

6. Connect the hose assembly to the top of cylinder

assembly (2).

7. Fill the hydraulic system to the correct level.

DISASSEMBLE BOWL LIFT CYLINDERS

Tools Needed

A

B

C

1P510

Drive Group

1

1P1784

Hydraulic Cylinder

Repair Stand

1

5P3100

Pump Group

1

1P850

Torque Multiplier

1

lP851

Adapter

1

1P852

Adapter

1

5S6077

Socket

1

1.

Remove bearings (I) from the cylinder (2) and

rod assembly (3) with tool group (A) and a

press.

2.

Place the cylinder on tooling (B).

3.

Slowly extend the cylinder to drain the oil.

Install a support under the rod. Fasten a strap

around the rod to secure the support. The

support will prevent the rod from dropping as

the cylinder head is pulled away.

4.

Unscrew head assembly (4) and pull cylinder

(2) away from rod and head assembly.

5.

Remove nut (5) and washer (6) that retains

piston (7) to rod (2) with tooling (C).

6. Remove piston (7) from rod.

7. Remove two rings (8) and seal assembly (9) from

piston (7).

8. Remove seal (10) from piston.

9. Remove seal (11) and ring (12) from head (3).

10. Remove plug (13) and unscrew gland assembly (14)

from head (3).

11. Remove packing (15) and washer (16) from head

(3).

12. Remove plug (17) and seal (18) from gland

assembly (14).

Refer to page 4-93 for illustration.

4-92